Part Machining / Mould

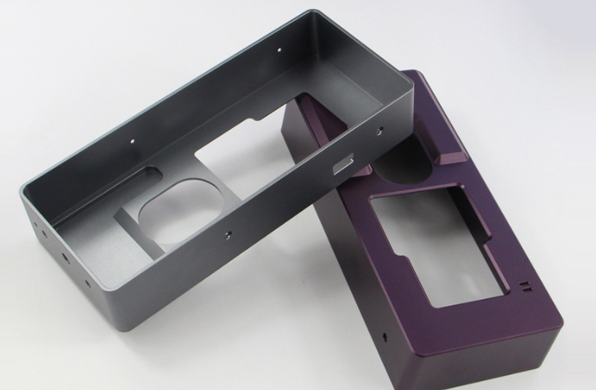

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

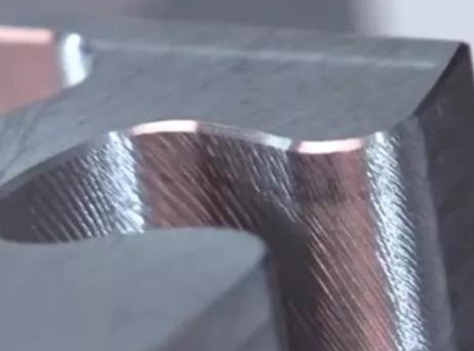

01 CNC Cutter Mark formation

The cut mark of CNC tool is achieved by contacting the cutting edge of the cutting tool with the component surface and moving it according to a predetermined path. In CNC machining, the shape and parameters of the cut mark can be precisely controlled by programming and controlling the CNC machine. The formation of cut marks can be achieved through different cutting processes such as milling, turning, and drilling.

CNC Cutter Marks can have different shapes, depths, densities and arrangements to create a variety of texture effects. Common CNC Cutter Marks include straight line, diagonal, cross, circular, curved, etc. These cut marks can be applied individually to specific areas of a component or combined to form more complex patterns or textures.

02、Use of CNC knife pattern

CNC Cutter Mark has an importance in the field of processing. The following are several aspects related to the importance of it:

Decorative effect: CNC Cutter Mark can add decorative effects to the surface of the component, making it more attractive and artistic.

Functional improvements: Some CNC Cutter Marks can provide additional functional improvements. Such as, the formation of CNC Cutter Mark on the surface of some mechanical parts can increase the friction coefficient and improve the grip or anti-slip performance of the parts. Moreover,CNC Cutter Marks can be used to enhance lubrication or improve gas or liquid flow characteristics.

Logo and Marking: CNC Cutter Marks can be used to mark in surfaces. Through the formation of Cut Marks, text, patterns or logos can be engraved on the part to identify product information, brand identity or other identification needs.

Precision control: Cut Marks can be used to help achieve more precise machining accuracy and dimensional control. By rationally designing the shape and distribution of Cut Marks, reference lines or marks can be provided during processing to more accurately control the processing position and size.

Heat dissipation and cooling: In some cases, cut marks can be used to increase part surface area to improve heat dissipation and cooling. By forming cut marks on the surface, the contact area between the part and the surrounding environment can be increased, thereby improving the efficiency of heat conduction and dissipation.

03、 How to run in CNC Cutter Marks

The running-in of CNC Cutter Marks refers to the process of gradually adapting and matching the knife tool and part surface through repeated contact and friction during the cutting process, reducing or eliminating tool marks. Here are some common methods for running in CNC Cutter Marks:

Proper cutting parameters: Choosing appropriate cutting parameters is very important for the break-in of cut marks. Reasonable feed rate, rotational speed and cutting depth can reduce cutting force and vibration, and help the running-in of the knife tool and the component surface.

Knife tool grinding and dressing: Make sure the blade of the knife tool is kept in good condition to avoid obvious wear or damage to the it. Regular tool grinding and dressing to ensure that the geometry and size of the knife tool blade meet the requirements will help reduce the formation of cut marks.

Knife tool lubrication and cooling: Using appropriate cutting lubricants and coolants can improve heat and friction during cutting. Lubrication and cooling help reduce cutting temperature, reduce cutting force, suppress vibration, and can improve the running-in effect between the knife tool and component surface.

Knife tool pre-break-in: Before formal machining, the pre-grinding process of the knife tool can be carried out. By cutting on some trial components for a period of time, the running-in of the surface of the knife tool and component can be promoted and the formation of cut marks can be reduced.

Processing sequence optimization: For complex components, a reasonable processing sequence can reduce vibration and cut marks during the cutting process. By adjusting the processing sequence and trying to avoid the knife tool repeatedly cutting the same area, the running-in effect of the knife tool and component surface can be improved.

It should be noted that the break-in of cut marks is a cumulative effect of time and process. When carrying out the running-in process, proper observation and monitoring are required, and adjustments and improvements are made according to the actual situation. In addition, factors such as the choice of knife tool material and component surface treatment will also affect the running-in effect of the cut mark.

04、Industrial Man| CNC machine

Industrial Man is a factory that has focused on CNC machining for 23 years. There are no middlemen, the quotations are fair, and we have been paying attention to the details. Now our company is fully equipped with processing capabilities from research and development, design and production. Strength is everything. Our factory have three-axis, four-axis, five-axis and gantry processing equipment. We have imported precision machining equipment, high processing precision, and excellent quality. We have been insisting on it!

As one of the top manufacturing brands in Guangdong, our company has a large amount of resource integration capabilities and provides full set services, which can satisfy various processing techniques! Therefore, all customers are welcome to come to our company for consultation and quotation!