Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

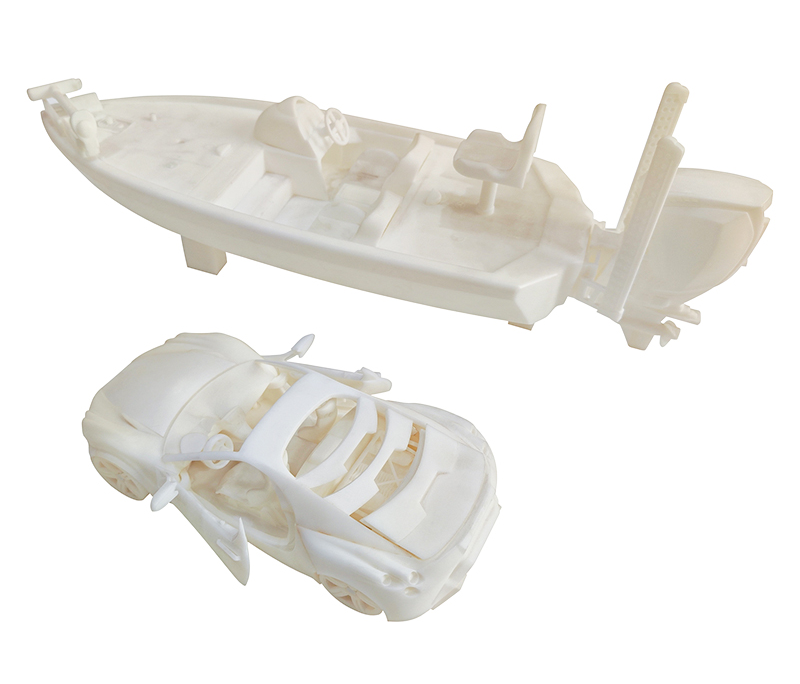

01、Nylon 3D printing

Nylon 3D printing is a process that utilizes nylon (polyamide) and other nylon-based materials as raw materials to create objects on a 3D printer. Nylon is a common engineering plastic that is widely used in 3D printing because of its good strength, abrasion resistance and chemical resistance.

In the nylon 3D printing process, the nylon material is heated to a molten state and the desired object is gradually built up by stacking layer upon layer. This method is known as Fused Deposition Molding (FDM) or Fused Deposition Modeling (FDF), and is one of the most common 3D printing techniques used today.

02、 Advantages of Nylon 3D Printing

Nylon 3D printing, a common method of printing engineering plastics, has some significant advantages and disadvantages. Here are the main advantages and disadvantages of nylon 3D printing:

Advantages:

(1) Strength and abrasion and chemical resistance:

Nylon material has good strength and abrasion resistance, making it suitable for parts and components that require durability. It also has good chemical resistance and can resist chemical corrosion to a certain extent, making it suitable for use in specific environmental applications.

(2) Design freedom:

With 3D printing technology, the design of complex geometries and structures can be achieved, providing greater flexibility for creativity and customization.

(3) Rapid prototyping:

Nylon 3D printing can be used for rapid prototyping, accelerating product development cycles and reducing development costs.

(4) Temperature stability:

Nylon materials have good temperature stability and are suitable for some applications in high temperature environments.

Despite some challenges, nylon 3D printing remains an attractive option in applications requiring high strength, wear resistance and design freedom. By capitalizing on its benefits, nylon 3D printing can play an important role in many areas of engineering and manufacturing.

03、 Comparison of FDM and SLS

Two common techniques used in 3D printing of nylon materials are Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS).

(i) FDM (Fused Deposition Modeling):

How it works: FDM is a common 3D printing technology that builds three-dimensional objects by heating plastic filament material to a molten state and then stacking it layer by layer through an extrusion head.

Nylon Applications: Nylon is often used as one of the printing materials in FDM and is suitable for making parts and functional assemblies due to its strength and abrasion resistance.

Advantages: easy to use, lower cost, suitable for making larger parts.

Disadvantages: Relatively low surface quality, support structure required, possible shrinkage problems.

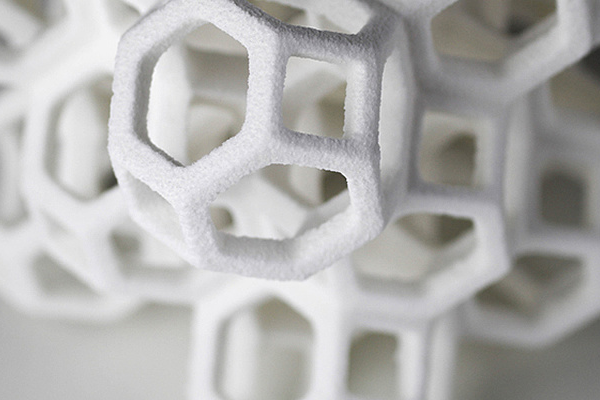

(ii) SLS (selective laser sintering):

How it works: SLS uses a laser beam to sinter powdered materials (such as nylon powder) together to form objects layer by layer without the need for a support structure.

Nylon Applications: Nylon is one of the commonly used materials in SLS and is suitable for making parts with high strength and complex structures.

Advantages: Complex geometries, high-quality surfaces and no need for support structures can be realized, making it suitable for mass production.

Cons: High equipment costs, slower printing speeds, higher costs.

When choosing a nylon material for 3D printing, the decision to use FDM or SLS technology can be based on factors such as product requirements, budget and design complexity.

04、 Nylon 3D Printing for Industrialists

Shenzhen Industrial Man is a manufacturing service company dedicated to product design and customized processing. Our company can engage in 3D/2D graphic design such as product modeling and structure, perfect industry and trade integration system, is the source manufacturer of quotation production. Industrial people sitting on 5w square meters of factories, 21 years of experience in processing, strength, the customer design of 3D graphics can be free quotes, direct CNC machining, rapid prototyping and mold manufacturing, etc., the output product quality is reliable, is really your right manufacturer in Guangdong!