Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

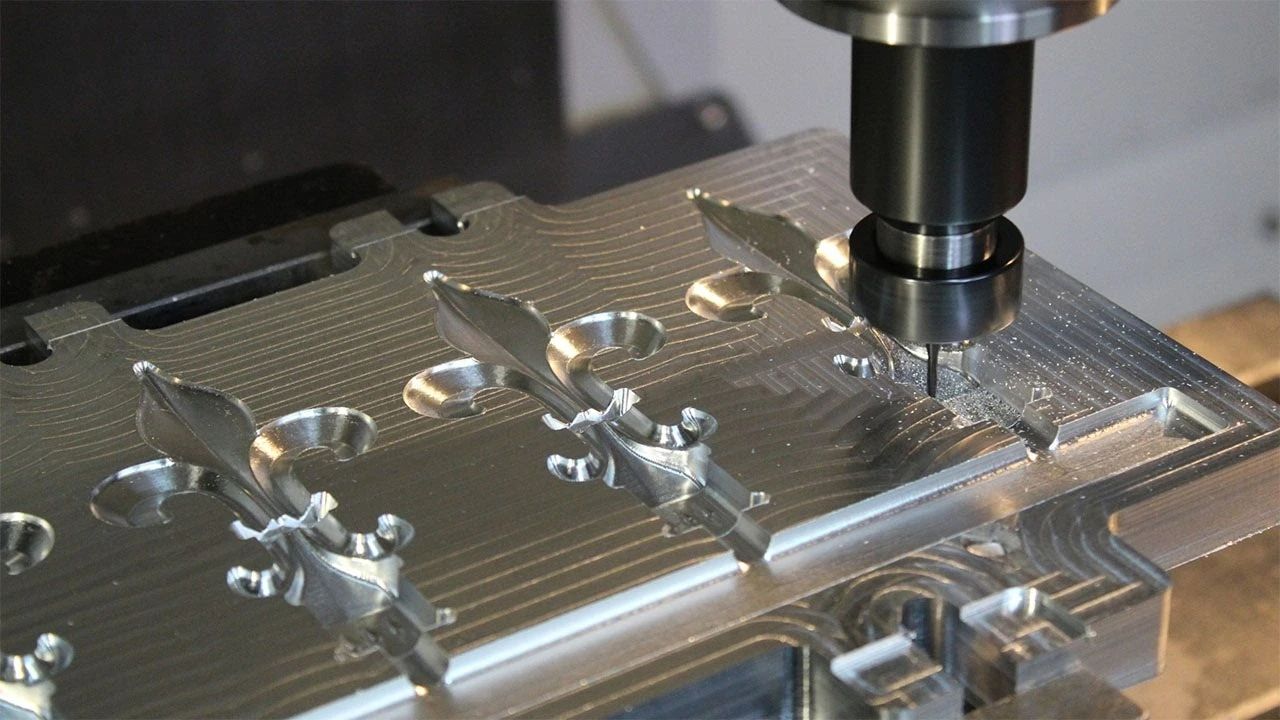

Exploring CNC machining: the core strength of precision manufacturing

Dear readers, welcome to today’s in-depth exploration of the manufacturing industry. In the vast world of modern industry, CNC machining is like a bright star, shining with a unique and charming light. Today, let us uncover its mysterious veil together and explore its mysteries and wonders.

CNC machining, the pioneer of change in manufacturing industry

Have you ever wondered how those exquisite metal parts and complex and precise industrial molds are manufactured? The answer is often hidden in the magical process of CNC machining.

CNC, Computer Numerical Control (Computer Numerical Control), has completely changed the traditional processing model. In the past, mechanical processing relied on the exquisite manual skills of master workers. Every operation needed to be completed manually, which was not only inefficient but also difficult to guarantee accuracy. However, with the advent of CNC machining technology, everything changed dramatically.

Today, through pre-written program instructions, CNC machine tools can automatically perform various processing operations on workpieces, such as milling, drilling, boring, tapping, etc. It is like a tireless intelligent craftsman, able to carve raw materials step by step into finished products that meet design requirements with extremely high precision and efficiency. Whether it is key components in the aerospace field, engine components in the automotive industry, or precision structural parts in elec-

tronic equipment, CNC processing plays an indispensable role and has become the core force driving the continuous development of modern manufacturing.

Excellent advantages of CNC machining

Stunning high-precision CNC

The precision of processing is unparalleled. It can control processing errors within a very small range, usually reaching micron or even sub-micron levels. What does this mean? It's like carving finely on a hair, every detail can be accurately presented. Such high precision makes the manufactured products a qualitative leap in performance and quality. For example, in the manufacturing of high-end optical instruments, CNC machining can ensure that the curvature and surface roughness of the lens are reached to the extreme, thereby providing users with a clear and precise visual experience.

Unparalleled efficiency

Time is money, especially in manufacturing. CNC machining has won valuable time and competitive advantages for enterprises with its efficient production capabilities. CNC machines can work 24 hours a day and process faster than traditional machining methods. It can quickly change tools, adjust pro-

cessing parameters, and complete complex processing tasks in a short time. Imagine that while other processing methods are still busy working on a part for hours or even days, CNC processing has mass-

produced a large number of high-quality products, greatly improving production efficiency and re-

ducing production costs.

High degree of flexibility and repeatability

The flexibility of CNC machining allows it to adapt to a wide variety of machining needs. Whether it is a simple geometric shape or a complex curved contour, it can handle it easily. Just by modifying the program instructions, the CNC machine tool can quickly switch processing tasks and produce products of different specifications and shapes. Moreover, once the procedure is determined, the consistency and stability of the product can be guaranteed no matter how many times it is processed. This repeatability is especially important for mass production, ensuring that every product reaches the same high-quality standards and establishing a good brand image for the company.

CNC machining application field awards

Aerospace: The heroes behind the dream of blue skies

In the aerospace field, every component carries a huge mission. CNC machining provides solid technical support for the manufacturing of aircraft, rockets and other aircraft. From the aircraft's wings and fuselage frame to the engine's turbine blades, combustion chambers and other key components, they are all inseparable from the precision manufacturing of CNC machining. These parts not only require extremely high strength and lightweight, but also require excellent high temperature resistance and corrosion resistance. With its high precision and high performance, CNC machining can meet these stringent requirements and help humans soar into the sky and explore the mysteries of the universe.

Automotive manufacturing: precision craftsmanship driving the future

The automobile industry is one of the important pillars of the national economy, and CNC ma-

chining plays a pivotal role in it. The engine is the heart of the car, and the accuracy of its internal components such as the crankshaft, piston, and cylinder block directly affects the performance and reliability of the engine. CNC machining can ensure high-precision machining of these parts, improving the engine's power output and fuel economy. In addition, CNC processing technology is also widely used in automobile transmissions, braking systems, suspension systems and other components, bringing drivers a safer, more comfortable and more efficient driving experience, and promoting the automotive industry to accelerate towards an intelligent and electrified future.

Electronic Communications: The Tiny Miracles That Connect the World

CNC machining is also present in the electronic communication equipment that is ubiquitous around us. The internal structures of electronic products such as mobile phones, computers, and tablets are becoming more and more complex, and their components are becoming more and more precise. CNC machining can produce tiny and precise circuit boards, connectors, heat sinks and other components to ensure the normal operation and high performance of electronic equipment. For example, the metal frame in a mobile phone can not only achieve an exquisite appearance design through CNC processing, but also have good heat dissipation performance, allowing us to enjoy the perfect integration of technology and craftsmanship while enjoying convenient communication and rich entertainment.

Medical Devices: Precision Guards for Health

In the field of medical devices, CNC processing protects human health. Surgical instruments, implantable medical devices, medical equipment casings, etc. all require high-precision, high-quality manufacturing processes. CNC machining can produce ergonomically designed medical devices with smooth and flawless surfaces, reducing surgical risks and improving treatment results. For example, the manufacture of artificial joints requires extremely high precision and biocompatibility. CNC processing technology can accurately create joint parts that perfectly match the human skeleton, allowing patients to regain health and freedom of movement.

The future of CNC machining

As technology continues to advance, CNC machining continues to innovate and develop. In the future, we will see more intelligent and automated CNC machining systems. Artificial intelligence technology will be widely used in processing process optimization, fault prediction and diagnosis, etc., to further improve processing efficiency and quality. At the same time, the continuous emergence of new materials will also bring new challenges and opportunities to CNC processing. CNC machining will continue to expand its application fields and play a more important role in emerging industries such as new energy, intelligent manufacturing, and biotechnology.

Dear readers, as one of the core technologies of modern manufacturing, CNC machining is changing our lives and shaping the future world with its outstanding advantages and wide range of applications. I hope that through today’s introduction, you will have a deeper understanding and understanding of CNC machining. If you are interested in CNC machining or have related processing needs, please feel free to communicate with us.