Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

Rapid prototyping technology

Rapid prototyping manufacturing technology, also known as rapid prototyping technology (RP technology); Multiple RP samples in the automotive application industry. After years of development, RP technology has basically formed a system. Similarly, the applicable industries have gradually expanded, from product design to mold design and manufacturing, materials engineering, medical research, cultural arts, construction engineering, and so on, all gradually using RP technology, making it have broad prospects.

What are the main components of rapid prototyping technology?

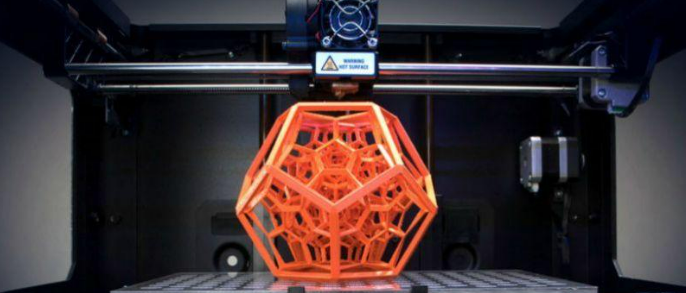

(1) 3D Printing, also known as additive manufacturing, is a technique that creates three-dimensional objects by stacking materials layer by layer. It uses computer-aided design (CAD) software to convert digital models into layer by layer printing instructions, and constructs objects by adding materials layer by layer.

(2) Laser sintering: It uses a laser beam to sinter powder materials (usually plastic or metal) layer by layer, causing their particles to combine with each other to form the desired object.

(3) Light curing: This technology uses ultraviolet laser beams or light cured resins to cure liquid resins layer by layer to construct objects. The laser beam scans on the liquid resin to solidify and harden it, gradually forming an object.

(4) Electron beam melting: This is a metal 3D printing technology that uses electron beam melting of metal powder to manufacture metal parts layer by layer. The electron beam scans the metal powder, causing it to melt and solidify, gradually forming an object.

(5) Melt deposition molding: It is a technology that extrudes molten materials layer by layer through a heated nozzle to construct objects. The material is heated by the nozzle while constructing objects by controlling the movement of the moving platform.

(6) Finite element analysis: Although not a direct manufacturing technique, it is a computational method used in the design process to simulate and analyze the behavior of objects. It is based on mathematical models and calculation methods, and can predict the response and performance of materials and structures under different conditions.

Application of Rapid Prototyping Technology in Stamping Sheet Metal

The application of rapid prototyping technology in the field of stamping sheet metal mainly includes the following aspects:

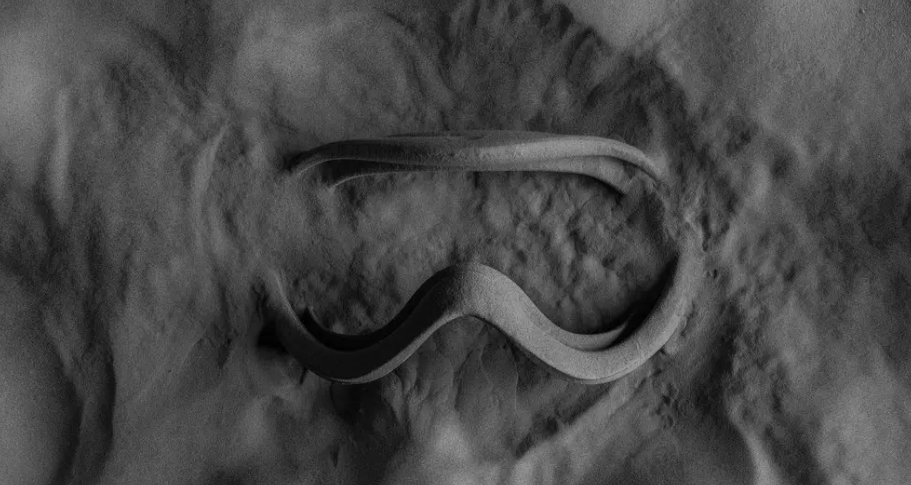

(1) Prototyping: Rapid prototyping techniques such as 3D printing can be used to create prototypes for stamped sheet metal products. Traditional prototyping usually requires the production of molds, which is time-consuming and laborious. However, using rapid prototyping technology can directly convert design files into physical models, quickly verify the feasibility of the design, and improve the efficiency of product development.

(2) Mold manufacturing: Stamping sheet metal production usually requires the use of molds to form and cut metal sheets. Rapid prototyping technology can be used to manufacture these molds. Through technologies such as 3D printing, complex shaped molds can be produced, reducing manufacturing cycles and costs, and improving production flexibility.

(3) Manufacturing of fixtures and fixtures: During the stamping process of sheet metal, various fixtures and fixtures are required to fix and position the workpiece. Rapid prototyping technology can be used to manufacture these fixtures. Through technologies such as 3D printing, corresponding fixtures can be quickly made based on the specific shape and size of the workpiece, improving production efficiency and quality.

(4) Part repair and replacement: In stamping sheet metal production, there may be situations where parts are damaged or need to be replaced. Rapid prototyping technology can be used for rapid repair or manufacturing of substitute parts. Through technologies such as 3D scanning and printing, geometric information of damaged parts can be obtained, and new parts can be quickly manufactured, reducing downtime and production costs.

Overall, the application of rapid prototyping technology in the field of stamping sheet metal can improve the efficiency of product development, reduce manufacturing cycles and costs, increase production flexibility, and enable quick repair and replacement of parts, improving production continuity and reliability.

Shenzhen Industrial Man Product R P & M Co., Ltd

As a professional rapid prototyping technology company in China, Industrial Man has complete basic processing equipment and strong technical strength. It has more than 400 CNC processing equipment and multiple precision 3D printing equipment, with excellent processing equipment and complete testing methods. The company has strong technical strength and a lean workforce, with multiple professional technical personnel including CNC machining department, mold design department, injection molding department, turning and milling department, sheet metal department, etc. It can maximize the 1:1 restoration and production of 3D drawing processing customization, meeting customer requirements.