Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

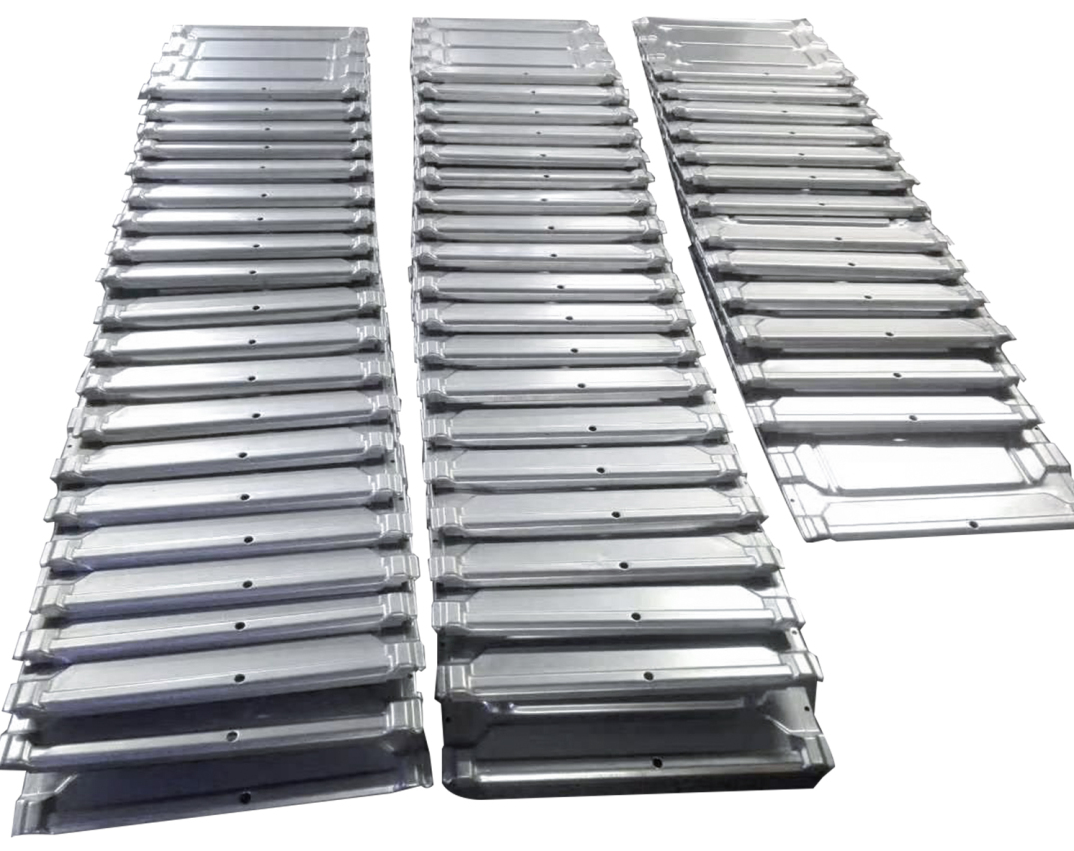

Surface treatments of sheet metal

The surface treatment of sheet metal plays a crucial role in product quality, functionality and appearance. The following are the specific cases of surface treatment for sheet metal:

Principle and function of sandblasting

Principle:

Sandblasting is the use of high-speed injection of sand particles to impact the sheet metal surface to remove the surface oxide layer, impurities and roughness, so as to achieve the effect of surface cleaning, increase roughness and improve adhesion.

Function:

(1)Remove the oxide layer and impurities: sandblasting can effectively remove the oxide layer, dirt and impurities on the surface of the stamping sheet metal, and purify the surface.

(2)Increase the surface roughness: after sandblasting, the roughness of the stamping sheet metal surface can be increased to a certain extent, which is conducive to the adhesion of the subsequent treatment such as coating and painting.

(3)Improve the surface quality: sandblasting treatment can improve the surface finish and flatness, and make the surface more uniform and consistent.

Principle and action of heat treatment

Principle:

Heat treatment is through the heating and control of the cooling process to apply the heat treatment on sheet metal parts, it will change its organizational structure and performance, to achieve the purpose of reinforcing materials.

Function:

(1)Improve the strength: the heat treatment can eliminate the internal stress and improve the grain structure, and improve the strength and hardness of the sheet metal.

(2)Improve toughness: through heat treatment, the toughness and ductility of sheet metal can be improved, so as to make it more durable and resistant to deformation.

(3)Adjustment of material properties: heat treatment can adjust the mechanical properties, physical properties and chemical properties of stamping sheet metal, so that it can adapt to different engineering requirements.

Principle and function of electroplating

Principle:

Electroplating uses electrochemical principles to deposit a layer of metal or alloy on the surface of sheet metal to increase its corrosion resistance, aesthetics and other specific properties.

Function:

(1)Improve the corrosion resistance: the electroplating layer can effectively prevent the oxidation and corrosion of the stamping sheet metal surface, and prolong its service life.

(2)Improve the appearance: electroplating can make the sheet metal surface with metallic luster, increase the beauty of the product.

(3) increase hardness: some electroplating layer can increase the hardness of stamping sheet metal surface, improve its wear resistance.

Principle and function of spraying

Principle: Spraying is sprayed on the sheet metal surface through the spray gun, forming a uniform coating.

Function:

(1)Protective surface: spraying can form a layer of protective film to prevent stamping metal from contact with the external environment and prolong its service life.

(2)Beautify products: spraying can change the color and appearance of stamping sheet metal, and improve the decoration of the product.

(3)Increase corrosion resistance: choosing the right coating can increase the corrosion resistance of stamping sheet metal and maintain the smooth finish of its surface.

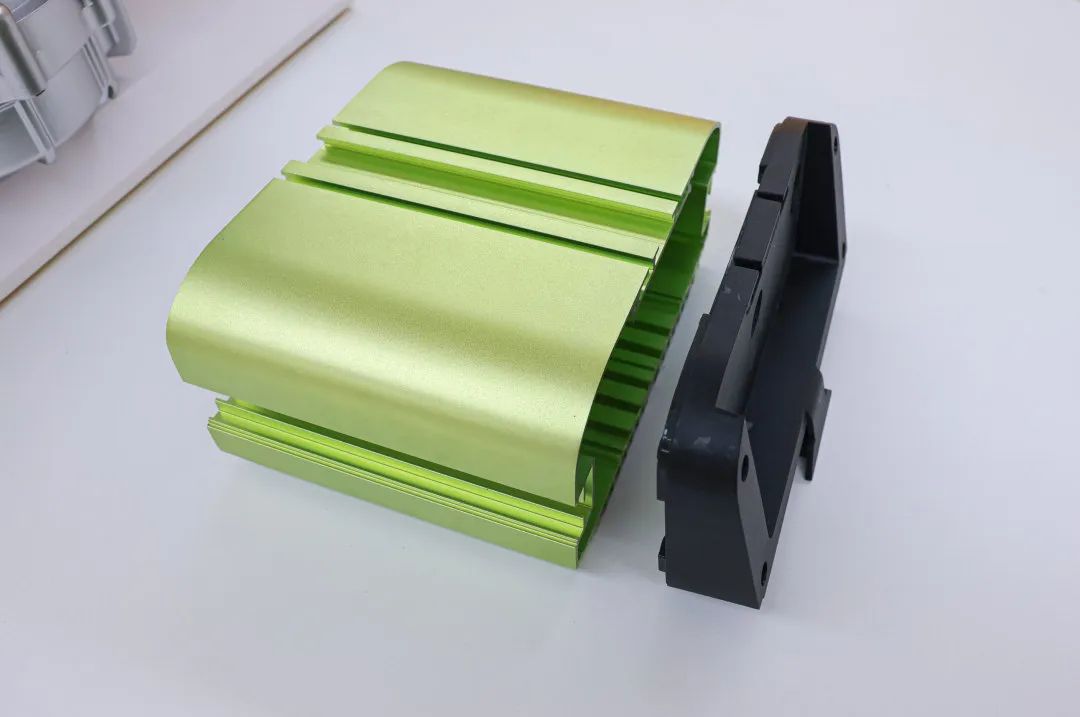

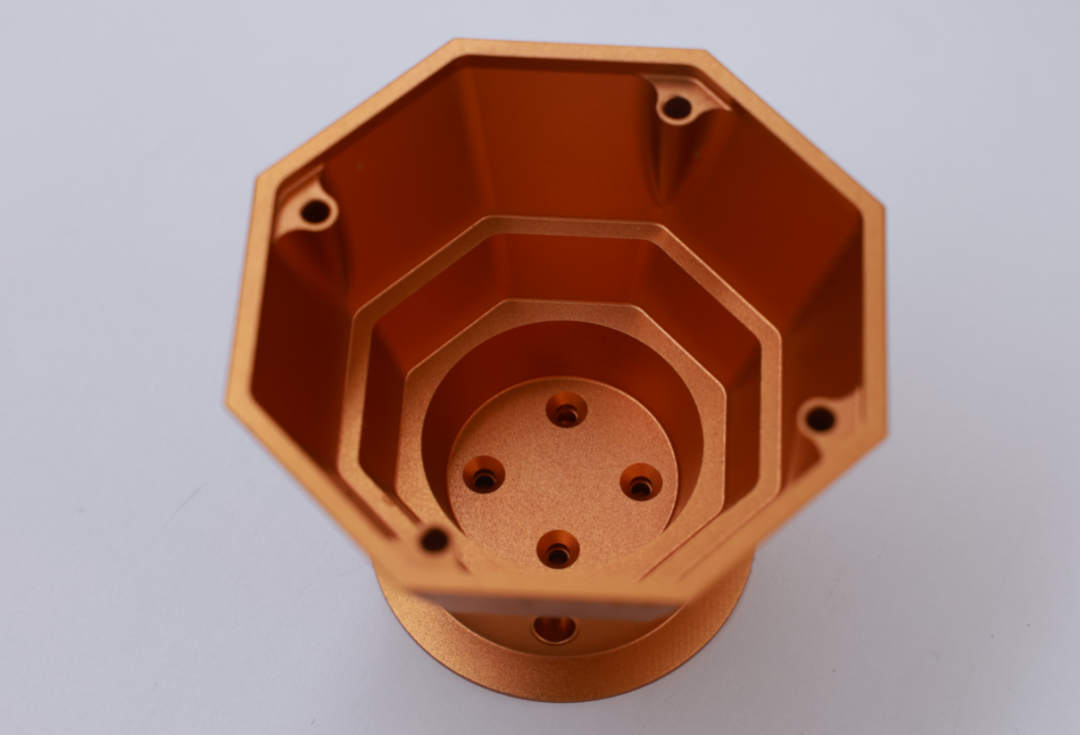

Principle and function of anodizing

principle:

Anodizing can improve surface hardness and corrosion resistance by forming an oxide film on the surface.

function:

(1)Improve the hardness: the anodizing treatment can increase the hardness of the sheet metal surface and improve its wear resistance.

(2)Service life.

(3)Beautify the surface: anodizing can make the stamping sheet metal surface present different color and texture, increase the beauty of the product.

Principle and function of polishing

Principle:

Polishing is the mechanical or chemical treatment of stamping sheet metal surfaces to remove the surface roughness and defects and make them smooth.

function:

(1)Improve the appearance quality: polishing can make the sheet metal surface become smooth, flattening, improve the appearance quality of the product.

(2)Increase the gloss: after polishing treatment, the gloss of the sheet metal surface will be improved, increasing the visual attraction of the product.

(3)Improve the surface flatness: polishing can eliminate the uneven and scratches on the surface, and improve the overall texture and beauty of the product.

Industrial man have something to say

The strong constant strong, one reason is that the skills will never be burden. In addition to the above surface treatment process, our company also has the surface treatments of brushing, painting, powder painting, radium carving(laser etching), blacken, electrophoresis, screen printing and so on, can protect, beautify and improve the performance of products in many aspects, to help customers to improve the quality of sheet metal products and market competitiveness. Over the years, our company has always upheld the product manufacturing as the core, customer’s satisfaction as the strength of the concept, adhere to the production of first-class products, establish the brand of industrial man professionals!! Sincere first, industrial man sincerely look forward to reaching a long-term friendly cooperation relationship with you!