Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

Driven by the wave of science and technology, humanoid robots are striding forward from science fiction into real life. The complex and sophisticated production process behind them is like a feast that brings together cutting-edge technology and innovative processes. It is quietly changing the landscape of the manufacturing industry and bringing new opportunities for optimizing the cost of industrial manufacturing processes.

Technology Integration Challenges

The integration of humanoid robot technology requires overcoming the difficulties of collaboration in multiple fields. Many companies have formed interdisciplinary teams through cooperation, integrating mechanical, electronic, software and other technical fields for in-depth collaboration, and coordinating the planning of hardware adaptation, data interfaces and system linkage in the production stage.

For example, Huawei has built automated production lines and industrial Internet platforms to achieve real-time data exchange and intelligent scheduling in the production process, and combined AI algorithms to optimize the assembly process. This not only ensures the precise assembly of complex components, but also dynamically adjusts process parameters through sensor feedback, significantly improving production efficiency and quality stability, and promoting the large-scale manufacturing upgrade of humanoid robots.

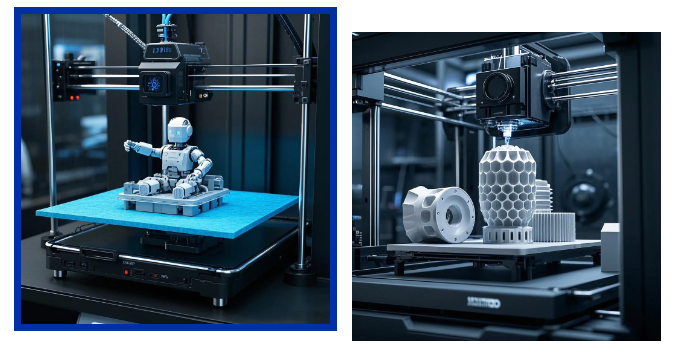

The revolutionary power of 3D printing

In the production of humanoid robots, 3D printing technology plays a unique role. On the one hand, it can quickly produce parts with complex shapes and realize customized production. For example, ANYbotics applies 3D printing technology to customize the leg structure of humanoid robots, solving the problem of adapting to special industrial environments (rough and corrosive) that are difficult to meet with traditional processes, and improving walking and corrosion resistance in complex terrain. On the other hand, 3D printing can use lightweight materials, and by optimizing the internal structure, it can reduce the overall weight of the robot and improve energy efficiency without reducing the strength of the parts.

For example, the shell of a printed robot can be designed with an internal honeycomb structure, which not only ensures the strength of the shell but also effectively reduces the weight. Industrial Man applies 3D printing technology to print a lightweight shell for a humanoid robot. By optimizing the material formula and printing process, the photosensitive resin material used has high strength while reducing the weight by more than 30% compared to traditional materials, greatly improving the robot's endurance and movement flexibility.

Towards large-scale intelligent production

Industrial Man closely follows the trend of large-scale production of humanoid robots, and builds an intelligent production system through the deep integration of sophisticated industrial processing technology with the Internet, big data, and AI technology. This technology integration not only achieves efficient and accurate connection from parts manufacturing to assembly and debugging, but also relies on real-time data monitoring and intelligent decision-making optimization to ensure high performance, low cost, and strict quality control of products, output cutting-edge intelligent solutions for the industrial manufacturing field, and accelerate the process of industrial upgrading.