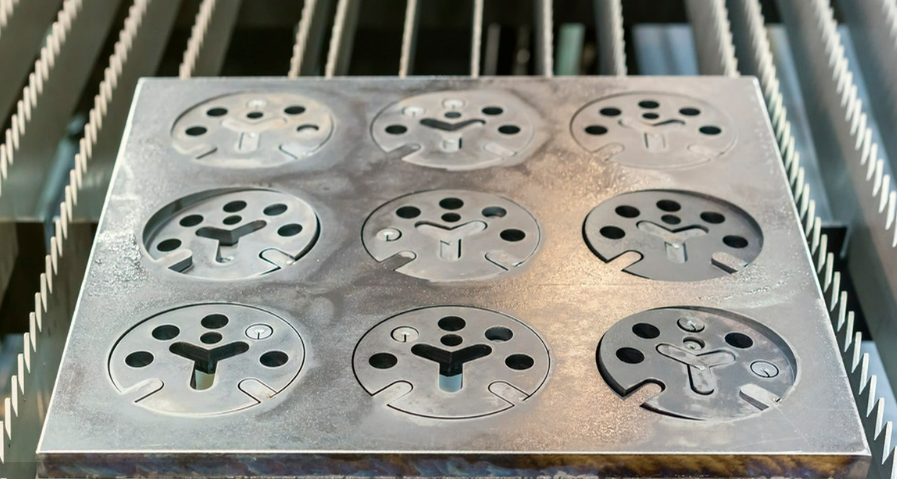

Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

1、 Systematic understanding of soft steel molds

Soft steel mold is a type of mold made from soft steel material. Soft steel is a type of steel with lower hardness and higher plasticity, typically possessing higher toughness and machinability.

Compared to traditional hard molds, soft steel molds have the following characteristics:

Materials: Soft steel has lower hardness, which makes it easier to be processed and modified. The plasticity and toughness of soft steel are relatively high, which helps to improve the plastic deformation and wear resistance of molds.

Manufacturing cost: Compared to hard molds, the manufacturing cost of soft steel mold is usually lower. Soft steel materials are relatively inexpensive and easy to process, and can be manufactured through simpler processes.

Rapid manufacturing and modification: Soft steel molds have high machinability and can be manufactured and modified in a short period of time. Therefore, Soft steel molds are suitable for personalized customization and small batch production, and can quickly respond to changes in market demand.

Adaptability: Soft steel molds can adapt to the manufacturing needs of products with different shapes and sizes. Due to the plasticity of soft steel, molds can be more easily adjusted in shape and modified in mold holes

Although soft steel molds have many advantages, they may not be suitable for manufacturing products that require high precision and quality due to the relatively low hardness of soft steel materials. For these situations, it is still necessary to use hard molds or other materials to meet the requirements.

2、How to choose a suitable soft steel mold?

When choosing the suitable soft steel mold material for oneself, the following factors can be considered:

Application requirements: The first thing to consider is what type of product the mold will be used to manufacture, as well as the characteristics and requirements of the product. Different products may have different requirements for mold materials, such as wear resistance, corrosion resistance, high temperature performance, etc. Understanding the usage environment and characteristics of the product can help determine the appropriate soft steel mold material.

Machinability: The machinability of soft steel molds is crucial for manufacturing and modifying molds. Choosing soft steel materials with good machinability can improve the manufacturing efficiency and modification flexibility of molds. Consider the plasticity, machinability, and weldability of soft steel materials.

Wear resistance and corrosion resistance: Soft steel molds usually need to have certain wear and corrosion resistance to ensure the lifespan and performance of the mold. Select soft steel materials with appropriate hardness, wear resistance, and corrosion resistance based on the usage environment and material contact conditions.

Cost and Availability: Considering the cost and availability of soft steel mold materials is also an important factor. Soft steel materials are usually relatively cheap and easy to obtain, but different types of soft steel materials may have different prices and supply situations. Based on budget and availability, choose economical and easily obtainable soft steel mold materials.

3、The impact and challenges brought by soft steel molds

In the era of personalized customization, soft steel molds are gradually replacing traditional formal mass production molds. Soft steel molds are a relatively flexible and cost-effective mold manufacturing method that can meet the rapid changes and diversity of personalized customization needs. The use of soft steel molds has indeed brought certain impacts and challenges to the traditional mold manufacturing industry. The following are specific manifestations:

Market demand changes: The rise of personalized customization has led to rapid changes and diversification in market demand. The traditional mold manufacturing industry usually focuses on large-scale production and long-term stable orders, while soft steel molds are more suitable for small batch and personalized production. This may lead to a decrease in the market share of traditional mold manufacturing industry, which needs to adapt to new market demands.

Manufacturing cost pressure: Soft steel molds have the advantages of low manufacturing costs and short manufacturing cycles. In contrast, traditional mold manufacturing typically requires more time and resources. This may lead to challenges for the traditional mold manufacturing industry in terms of cost competition, requiring process optimization and efficiency improvement to reduce manufacturing costs.

Technical transformation and training needs: The manufacturing and use of soft steel molds require certain skills and techniques. The traditional mold manufacturing industry may need to undergo technological transformation, learning the manufacturing and usage techniques of soft steel molds. This may require training existing workers or hiring new technical talents to adapt to new manufacturing methods.

Intensified market competition: With the popularization and application of soft steel molds, market competition may intensify. The traditional mold manufacturing industry needs to compete with soft steel mold manufacturers not only in terms of price, but also in providing higher quality and precision products and services to maintain competitiveness.

Although soft steel molds pose some challenges to the traditional mold manufacturing industry, it still has its own advantages. For products that require high precision, high quality, and long-term stable production, traditional molds are still indispensable. Therefore, the traditional mold manufacturing industry can respond to the impact of soft steel molds through innovation, technological upgrades, and market positioning adjustments, and seek new business opportunities and competitive advantages.

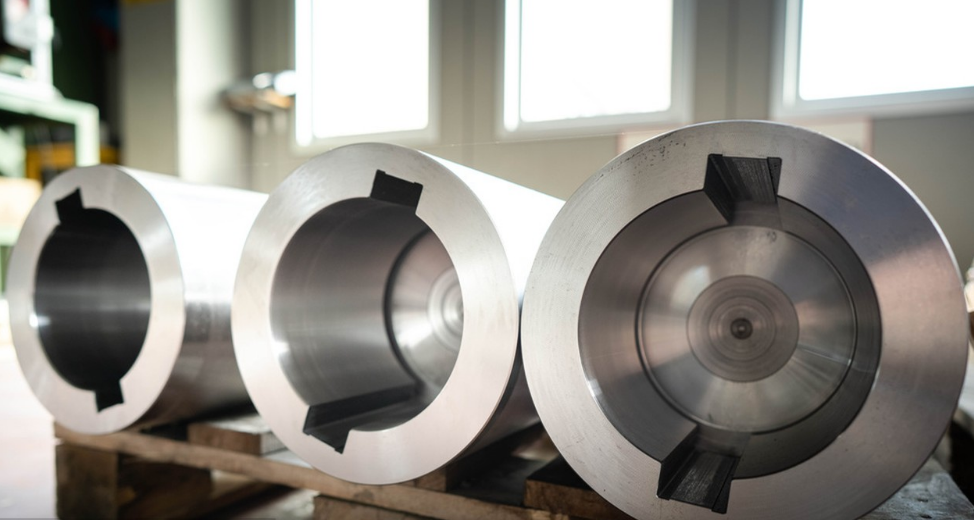

4、 Soft steel molds,Industrial Man are superior

Industrial Man inherit craftsmanship, strive for excellence, and focus on professional steel mold manufacturers for production and sales. Customizable parameters and more model choices are available! As a steel mold manufacturer with low prices in the industry, our company supports online procurement, real-time inquiry, and wholesale selection. We will adopt formal production processes and product materials that meet the performance requirements of formal materials, suitable for parts with high material performance and structural requirements. The molds are made of soft steel, such as P20, 718, etc. This not only simplifies mold design, but also saves mold development costs and development cycles.

Industrial Man welcome your inquiry and visit!