Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

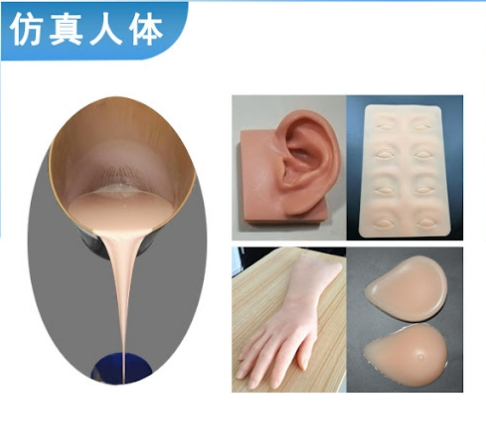

01 Advantages of Silicone Molding Compared to Traditional Methods in Medicine

There are several contrasts between traditional medical devices and medical devices made from silicone molding:

Personalized Adaptability: Traditional medical devices are typically designed for general use and may not fully adapt to the anatomical structure and needs of each patient. Medical devices made from silicone molding, on the other hand, can be manufactured based on patient's scan data and customized techniques, providing personalized adaptability that better fits the patient's body parts.

Biocompatibility: Silicone molding exhibits excellent biocompatibility in the medical field, as it is compatible with human tissues and reduces stimulation and rejection reactions in patients. In contrast, the materials used in traditional medical devices may not possess good biocompatibility, which can lead to allergic reactions or other adverse effects.

Functionality and Simulation: Medical devices made from silicone molding can achieve high levels of functionality and simulation. For example, simulated tissues and artificial organs can provide structures and functions that closely resemble natural tissues, thus better meeting the needs of patients. Traditional medical devices may not offer the same degree of functionality and simulation.

Customization and Precision: Medical devices made from silicone molding can be custom-manufactured based on individual patient characteristics, providing more precise medical solutions. In comparison, traditional medical devices are often designed for general use and may not accommodate individual variations and needs of each patient.

Manufacturing and Adaptability: Medical devices made from silicone molding typically require scanning and custom manufacturing, involving complex processes that require specialized technical support. Traditional medical devices, on the other hand, are typically mass-produced and distributed, resulting in lower manufacturing and adaptability

02 Applications of Silicone Molding in Medical Devices

When it comes to the application of silicone molding in medical device manufacturing, here are some specific details:

Personalized Device Manufacturing: Silicone molding can be used to manufacture personalized medical devices that adapt to the patient's anatomical structure and needs. For example, using the patient's scan data, custom prosthetics, implants, and scaffolds can be created. Silicone molding can accurately replicate the patient's anatomical features and be used to produce customized devices, providing better fit and functionality.

Bionic tissues and artificial organs: Silicone replicas have important applications in the manufacture of bionic tissues and artificial organs. For example, silicone molding technology is often used in breast implant manufacturing to achieve a high degree of simulation in shape and texture. In addition, silicone replica molds are also used to manufacture devices such as artificial heart valves, artificial blood vessels, and artificial skin to provide better biocompatibility and functionality.

Drug delivery systems: Silicone replica molds can be used to manufacture drug delivery systems such as microsyringes and implantable drug pumps. These devices often require precise construction and volume to ensure accurate delivery and release of the drug. Silicone replicas can be used to make molds for these devices and achieve the required accuracy and performance by controlling the mold design and manufacturing process.

Surgical auxiliary tools: Silicone replicas are also used in the manufacture of surgical auxiliary tools. For example, silicone replicas can be used to create surgical simulators and models to aid doctors in surgical rehearsal and training. These simulators and models can provide a realistic feel of anatomy and tissue, allowing physicians to become familiar with surgical techniques in practice.

Diagnostic and monitoring devices: Silicone replica molds can be used to manufacture a variety of diagnostic and monitoring devices, such as biosensors and medical sensors. These devices often require highly sensitive sensors and accurate structures to acquire and transmit biological signals and data. Silicone replicas can be used to create molds for these devices, allowing for precise structure and performance.

03 Witness the strength of industrial silicone molding

Industrial man has 20 years of expertise in vacuum molding, which is widely used in robots, medical equipment, etc. As long as you provide 3D drawings or STP/STL format files, our company will customize and process it according to your quantity, materials, post-processing methods and other special requirements. After the product is completed, it can achieve exquisite workmanship, high assembly precision, quality assurance, It has the characteristics of mold opening, low production cost, fast delivery, and supports small batch customization. Bosses are welcome to come to us for drawing consultation, and we will tailor it for you!