Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

01 Common Materials for Metal 3D Printing

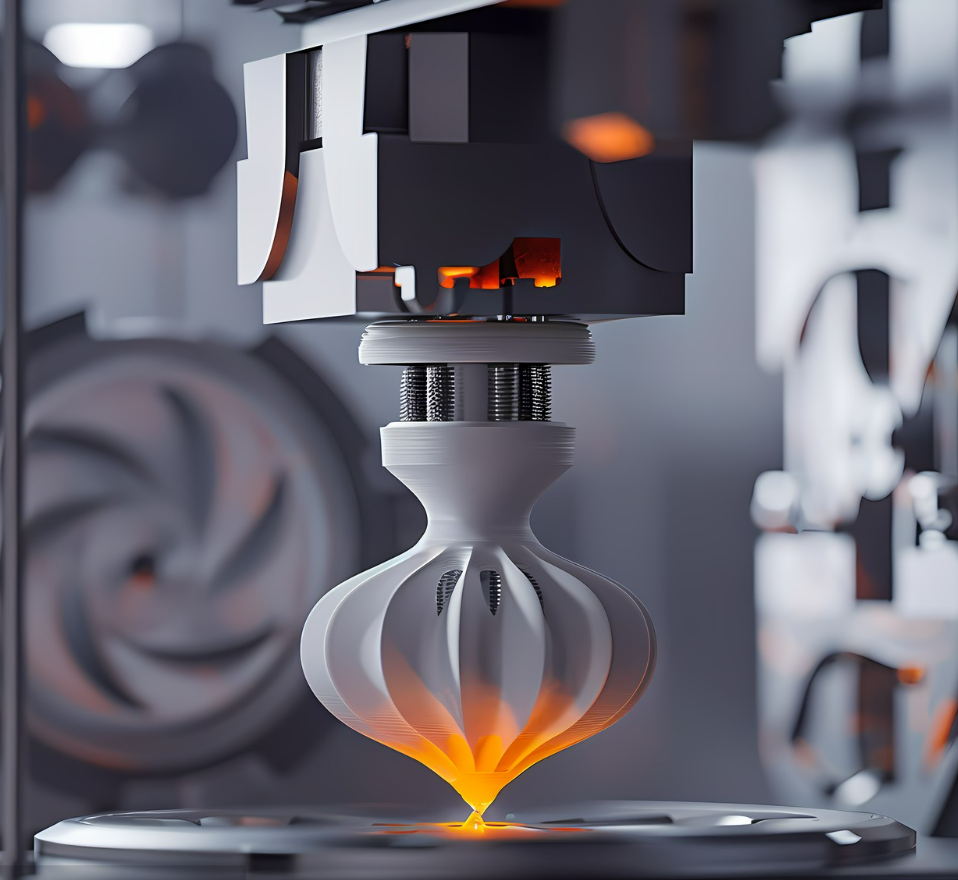

Metal 3D printing is an advanced manufacturing technology that uses metal materials to create three-dimensional objects. It is also known as metal additive manufacturing or metal 3D printing. The commonly used materials include stainless steel, aluminum alloy, and titanium alloy, each having distinct physical properties, mechanical performance, and application fields.

(1) Physical Properties:

Stainless Steel: Stainless steel is an iron-based alloy mainly composed of iron, chromium, nickel, and other alloying elements. It has good corrosion resistance and mechanical properties, making it suitable for various environments and applications. Stainless steel has a relatively high density but a comparatively low thermal conductivity.

Aluminum Alloy: Aluminum alloy primarily consists of aluminum, with the addition of other alloying elements (such as copper, zinc, magnesium, etc.) to enhance its properties. It has a lower density, good strength, and excellent thermal conductivity, making it suitable for applications requiring lightweight and thermal conductivity.

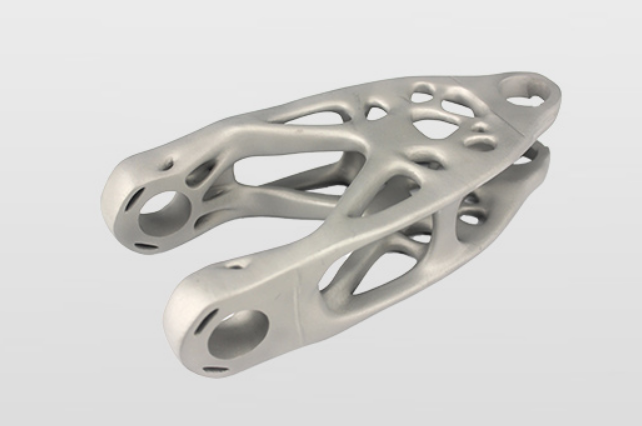

Titanium Alloy: Titanium alloy primarily consists of titanium, with other alloying elements (such as aluminum, vanadium, nickel, etc.) added to improve its performance. It has a low density, high strength, and excellent corrosion resistance, making it suitable for applications requiring high strength and corrosion resistance.

(2) Mechanical Properties:

Stainless Steel: Stainless steel has high strength, hardness, and wear resistance. It maintains good performance stability in high and low-temperature environments and has high tensile and compressive strength.

Aluminum Alloy: Aluminum alloy has a lower density and good toughness, with moderate strength and hardness. It is lighter than stainless steel, but its relatively low hardness limits its use in high-strength applications.

Titanium Alloy: Titanium alloy has a high specific strength (the ratio of strength to density), good corrosion resistance, and high-temperature strength. It is lighter than stainless steel and aluminum alloy but also more expensive.

02 Application Fields and Product Examples of the Three Materials

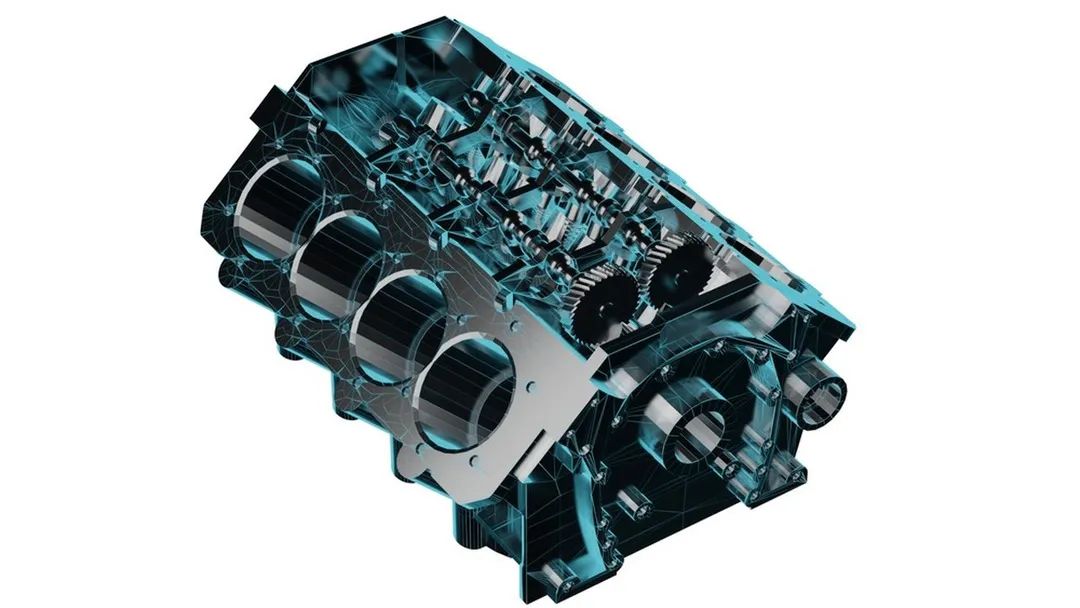

(1) Stainless Steel in Metal 3D Printing:

1.Industrial Parts and Components: Stainless steel can be used to manufacture various industrial parts and components, such as valves, pump bodies, fixtures, and tools. Its corrosion resistance and high-temperature performance make it suitable for diverse industrial environments.

2.Piping and Pipe Fittings: Stainless steel is widely used in piping systems. Metal 3D printing can produce complex-shaped pipes and pipe fittings, suitable for various industrial and construction applications.

3.Medical Devices and Implants: Stainless steel is extensively used in the medical field to manufacture medical devices and implants. Metal 3D printing can create complex-shaped medical devices and personalized implants, such as surgical tools, bone plates, and joint implants.

4.Aerospace and Automotive Industries: Stainless steel can be used to manufacture components and structures in the aerospace and automotive industries. Metal 3D printing enables the creation of complex geometries and lightweight designs, improving product performance and reducing weight.

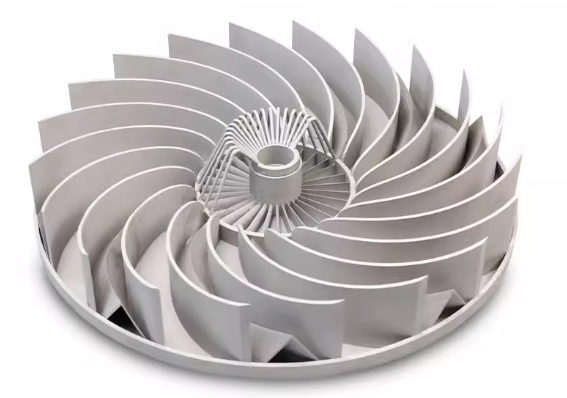

(2) Aluminum Alloy in Metal 3D Printing:

1.Aerospace Field: Aluminum alloy is widely used in the aerospace field to manufacture aircraft structural parts, engine components, and drone parts. Its lightweight, high strength, and corrosion resistance make it an ideal choice for the aerospace industry.

2.Automotive Industry: Aluminum alloy is extensively used in the automotive industry to manufacture car parts, such as engine hoods, body structures, and chassis components. The lightweight nature of aluminum alloy helps improve fuel efficiency, reduce vehicle weight, and offers good formability and machinability.

3.Electronics Field: Aluminum alloy is increasingly used in electronic devices, such as heat sinks, housings, and electronic packaging. The thermal conductivity of aluminum alloy makes it an excellent material for heat dissipation, and metal 3D printing can create complex heat dissipation structures.

4.Construction and Building: Aluminum alloy is used in construction and building for making doors, windows, facade structures, and bridges. Its lightweight, weather resistance, and formability make it an ideal construction material.

5.Industrial Equipment and Fixtures: Aluminum alloy can be used to manufacture industrial equipment and fixtures, such as jigs, fixtures, and assembly tools. Its customizability and good machinability make it suitable for various industrial applications.

(3)Titanium Alloy in Metal 3D Printing:

1.Aerospace: Crucial for manufacturing aerospace engine parts, turbine blades, and structural components.

Medical Field: Widely used for manufacturing implants and medical devices, such as artificial bones, joint implants, and dental brackets.

2.Automotive Industry: Used for manufacturing automotive parts like engine components, chassis structures, and brake systems. Its lightweight and high strength characteristics help improve fuel efficiency and performance.

3.Energy Industry: Applied in energy sectors including oil and gas extraction equipment, nuclear equipment, solar, and wind energy equipment.

4.Manufacturing and Industrial Equipment: Used for manufacturing various industrial equipment and components like valves, pump bodies, fixtures, and tools. Its corrosion resistance and high-temperature performance make it suitable for diverse industrial environments.

As a leader in 3D printing, Industrial Man employs over thirty professional technicians and operates multiple types of 3D printers along with hundreds of post-processing equipment lines. With solid expertise, Industrial Man offers multi-size, multi-structure, multi-material, batch, and continuous metal 3D printing services.We enable lightweight designs, minimize excess parts, and create complex shapes suitable for manufacturing non-moldable and tool-free parts. We also accommodate small batch production, ensuring high-efficiency workmanship, ultimately enhancing product quality and reducing energy consumption.