Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

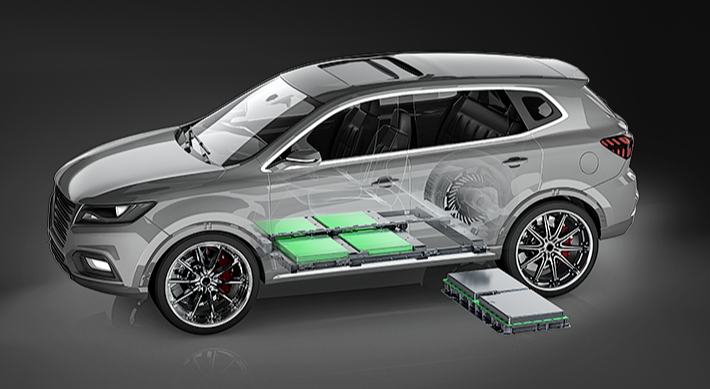

01、New energy vehicle battery pack chassis liquid cooling system

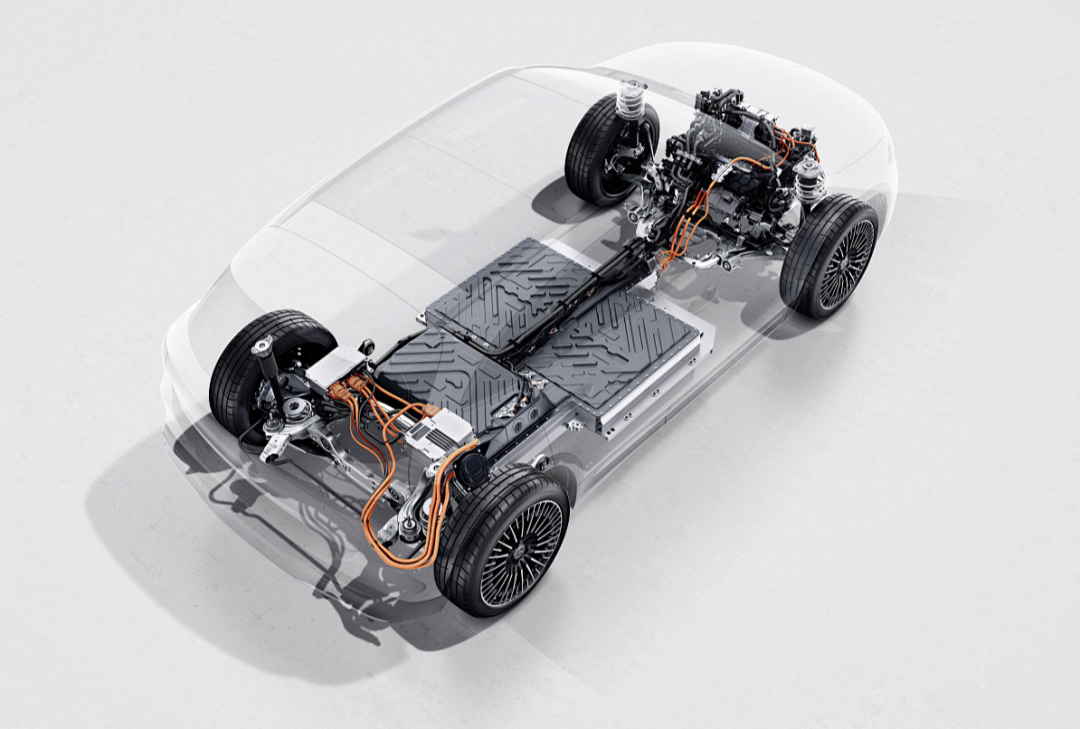

The new energy vehicle battery pack chassis liquid cooling system refers to a system that controls the battery pack temperature through liquid cooling technology. In electric vehicles, the battery pack is a key component of the entire vehicle, and the performance and life of the battery depend largely on its operating temperature. Therefore, keeping the battery within a suitable temperature range is crucial to the efficiency and life of the battery.

The liquid cooling system absorbs the heat generated by the battery by arranging cooling pipes around the battery pack and circulating coolant through these pipes, thereby maintaining the battery temperature within an appropriate range. This system can effectively control the battery temperature, prevent overheating or over-cooling, and improve the efficiency and life of the battery.

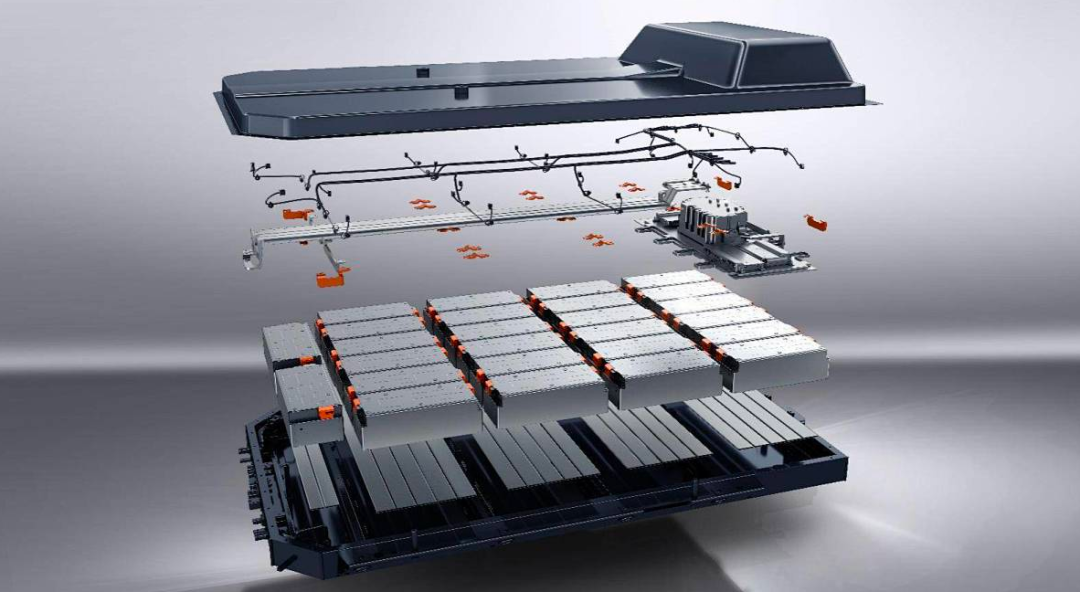

02、The role of liquid cooling plate stamping in liquid cooling system

The liquid cooling plate stamping in the liquid cooling system of the new energy vehicle battery pack chassis plays an important role in the entire system. Its functions are as follows:

Optimized heat dissipation effect: The design of the liquid cooling plate can achieve complex internal structures through the stamping process, increase the surface area, improve heat conduction efficiency, and thereby effectively dissipate heat. This helps to reduce the temperature of the battery pack and improve the working efficiency and life of the battery.

Lightweight design: The stamping process can produce a thin but structurally strong liquid cooling plate according to design requirements, which helps to reduce the weight of the entire liquid cooling system and improve the energy efficiency and mileage of the car.

Compact structure: The stamping process can achieve a compact design of the liquid cooling plate, so that the liquid cooling plate occupies less space inside the battery pack chassis, thereby retaining the effective volume of the battery pack to the greatest extent.

High manufacturing efficiency: The stamping process has a high degree of automation and production efficiency, and can quickly and accurately manufacture a large number of liquid cooling plates of the same specifications, which is conducive to mass production and reducing manufacturing costs.

Easy to integrate: The stamped liquid cooling plate can be easily integrated into the battery pack chassis liquid cooling system according to design requirements, and works well with other components to ensure the normal operation of the entire liquid cooling system.

Therefore, the role of liquid cooling plate stamping in the liquid cooling system of the new energy vehicle battery pack chassis is critical. It not only affects the heat dissipation effect and performance of the system, but also directly affects the energy consumption and driving performance of the vehicle.

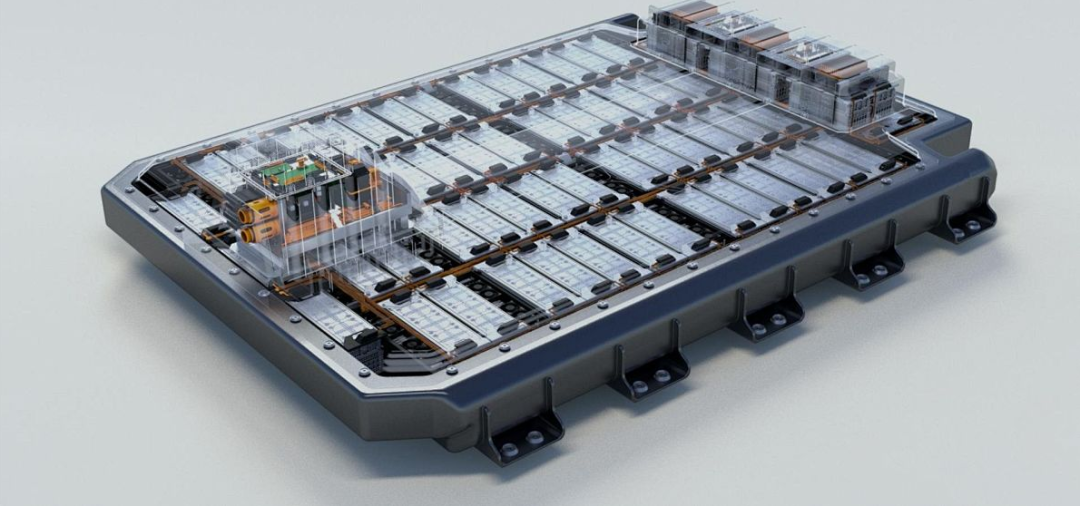

03、What are the latest trends in liquid cold plate design?

Liquid cooling plates play a vital role in the liquid cooling system of the battery pack chassis of new energy vehicles. Their design trends are constantly driven and influenced by technology and the market. Here are some of the latest trends in liquid cooling plate design:

Efficient heat dissipation design: In view of the increasing power density of electric vehicle battery packs, the design of liquid cooling plates tends to adopt more efficient heat dissipation structures, such as increasing the surface area and optimizing the internal flow channel design to improve heat dissipation efficiency and ensure that the battery pack can maintain a suitable temperature under high power operation.

Lightweight and compact design: As the requirements for electric vehicle range and energy efficiency continue to increase, the design of liquid cooling plates tends to be lightweight and compact. By optimizing structural design and material selection, the weight and size of the liquid cooling plate can be reduced, and the energy density and mileage of the entire vehicle can be improved.

Integrated design: Taking into account the needs of space utilization efficiency and system integration, the design of liquid cooling plates tends to be integrated, that is, the heat dissipation structure, cooling pipelines and other functional components are integrated on one board to simplify the system structure, reduce the number of components and reduce manufacturing costs.

Intelligent functions: With the development of intelligent technology, the design of liquid cooling plates tends to integrate intelligent sensing and control functions, such as temperature sensors, flow control valves, etc., to achieve real-time monitoring and adjustment of battery temperature and cooling system, and improve system stability and efficiency.

Sustainability and Environmental Protection: In the design of liquid cold plates, more and more attention is paid to sustainability and environmental protection, including the use of recyclable materials, optimizing production processes to reduce energy consumption and waste generation, and other measures to reduce the impact on the environment.

These trends reflect the continuous pursuit of higher efficiency, lighter weight, smarter and more sustainable liquid cooling plate designs to meet the high performance and environmental requirements of new energy vehicle battery systems.

04、Together we will create an industrial powerhouse under the new energy

With the birth of new energy vehicles, its related industrial chain has emerged like a galaxy of stars. Industrial people have also gradually emerged, not only specializing in related industries such as auto parts, interior decoration, and models, but also combining their own advantages to seek innovation in chassis. In recent years, the heat dissipation technology studied by our technical personnel can provide customers with customized new energy vehicle battery pack chassis radiator design and manufacturing services, accept new energy liquid cooling plate professional customization of various radiators, water cooling plates, and can provide production links from design and development, simulation, proofing verification, mass production, etc., which can meet diversified customization needs at multiple levels and add strength to the exploration of domestic new energy!