Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

Rapid tool and Vacuum Casting

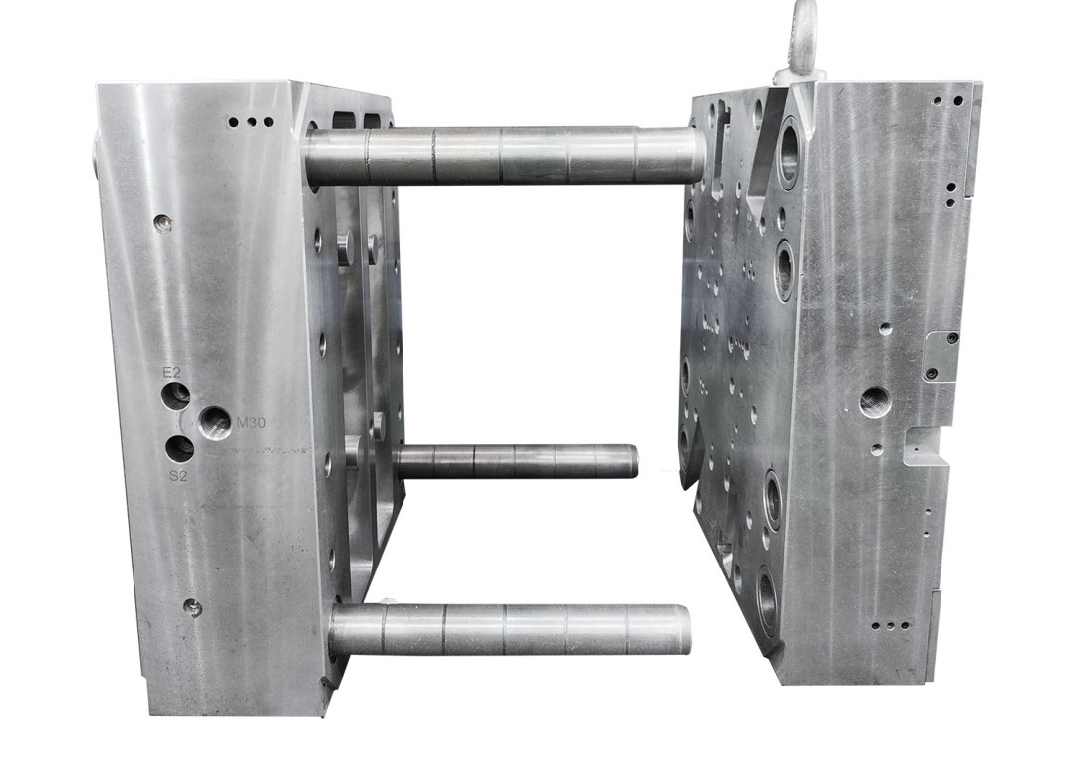

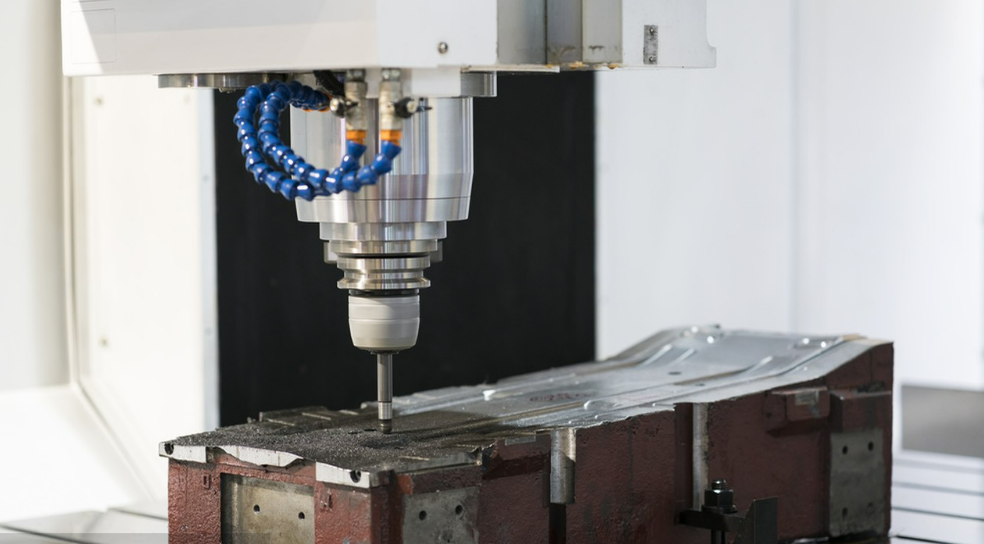

Rapid tool is usually used in rapid prototyping, small batch production and other fields, suitable for the need for rapid development and production. Rapid tool are usually made of rigid materials such as metal (such as aluminum, steel) or resin, which have high durability and wear resistance.

Vacuum casting are usually made by soaking the prototype in silicone, let the silicone solidify into a mold, and then pouring the required material into the mold to copy the prototype. This technique is suitable for the production of complex, fine products, often used in art, models, toys and other fields. Silicone mould are relatively fragile and suitable for smaller batch production.

differences

materials

Rapid tool: usually made of rigid materials such as metal (such as aluminum, steel, etc.) or resin.

Silicone mould: The use of soft silicone material, with a certain flexibility and elasticity.

Production process

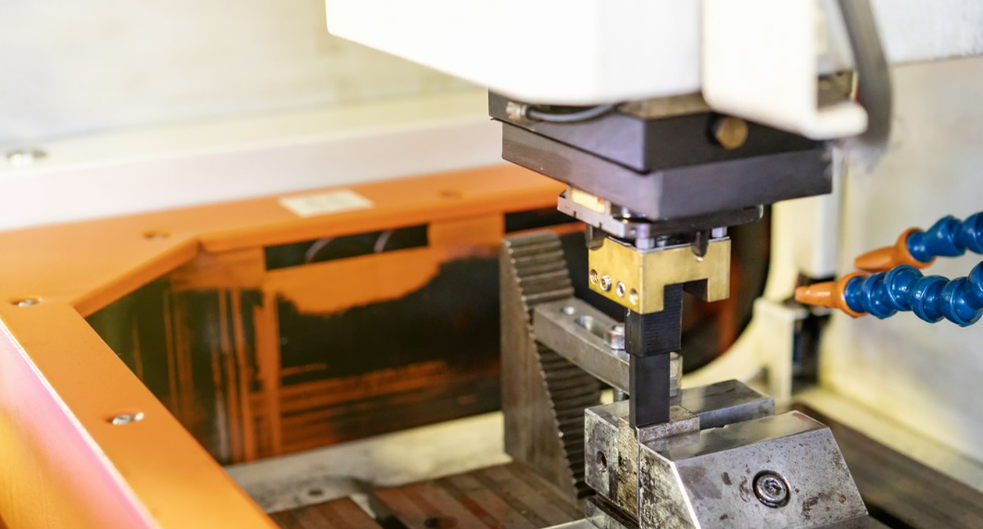

Rapid tool: usually through CNC machining and other digital technology to make moulds, suitable for industrial production.

Silicone mould: by soaking prototype, curing silicone and other manual processes, suitable for art, models and other fields.

suitable fields

Rapid tool:It is mainly used in industrial production fields, such as rapid prototyping, small batch production, etc.

Silicone mould: More commonly used in art, sculpture, toys, models and other fields.

durability

Rapid tool:Usually has high durability and wear resistance, suitable for mass production.

Silicone mould: It is relatively fragile and is usually suitable for smaller batch production.

In summary, rapid tool and silicone mould in the material, production process, application field and durability, there are obvious differences, but they are special technologies for mold production, each play an important role in different fields.

The scope of application of both

Rapid tool and silicone mould have their own unique application range in different fields, as shown below:

Application range of rapid tool:

Rapid prototyping: Used to quickly prototype products for design validation and functional testing.

Small batch production: suitable for the need to quickly produce a small number of products, can reduce manufacturing costs and speed up the production cycle.

Customized parts production: It can quickly produce customized parts that meet the individual needs of customers.

Repair and replacement parts: Used to quickly manufacture replacement parts and extend the service life of the product.

Modification and upgrading: used to manufacture modified parts that meet individual needs, such as automotive modification and other fields.

Art and sculpture production: often used to produce art, sculpture and other complex shape products.

1. Toy manufacturing: Silicone molds are often used to make complex parts or wholes of toys.

2. Model making: suitable for making various parts of models, such as aircraft models, vehicle models, etc.

3. Jewelry making: Intricate designs and elaborate parts used to make jewelry.

4. Handicrafts: Often used to make complex or delicate parts in handicrafts.

5. Electronic product shell: suitable for making small batch electronic product shell or parts.

6. Food production: In the food industry, silicone molds can also be used to make chocolate, candy and other complex shapes of food.

In general, rapid tool is mainly used in industrial production fields, such as rapid prototyping and small batch production, while silicone mould is more used in art, models, toys and other fields, suitable for the production of products requiring fine and complex shapes.

Industrial Man | mold customization experts at your side

As a large mold factory in Guangdong Province, Industry Man provides customers with rapid mold one-stop design and service, and is a silicone products manufacturer. Our company adhering to cost-effective, reliable quality, can come to sample mould customization! Now specializing in the production of automotive silicone, medical silicone, household appliances silicone, silicone maternal and child products and other silicone and mold products for more than 20 years, looking for industry source manufacturers, Shenzhen industrial Man, welcome customers to come to consult!