Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

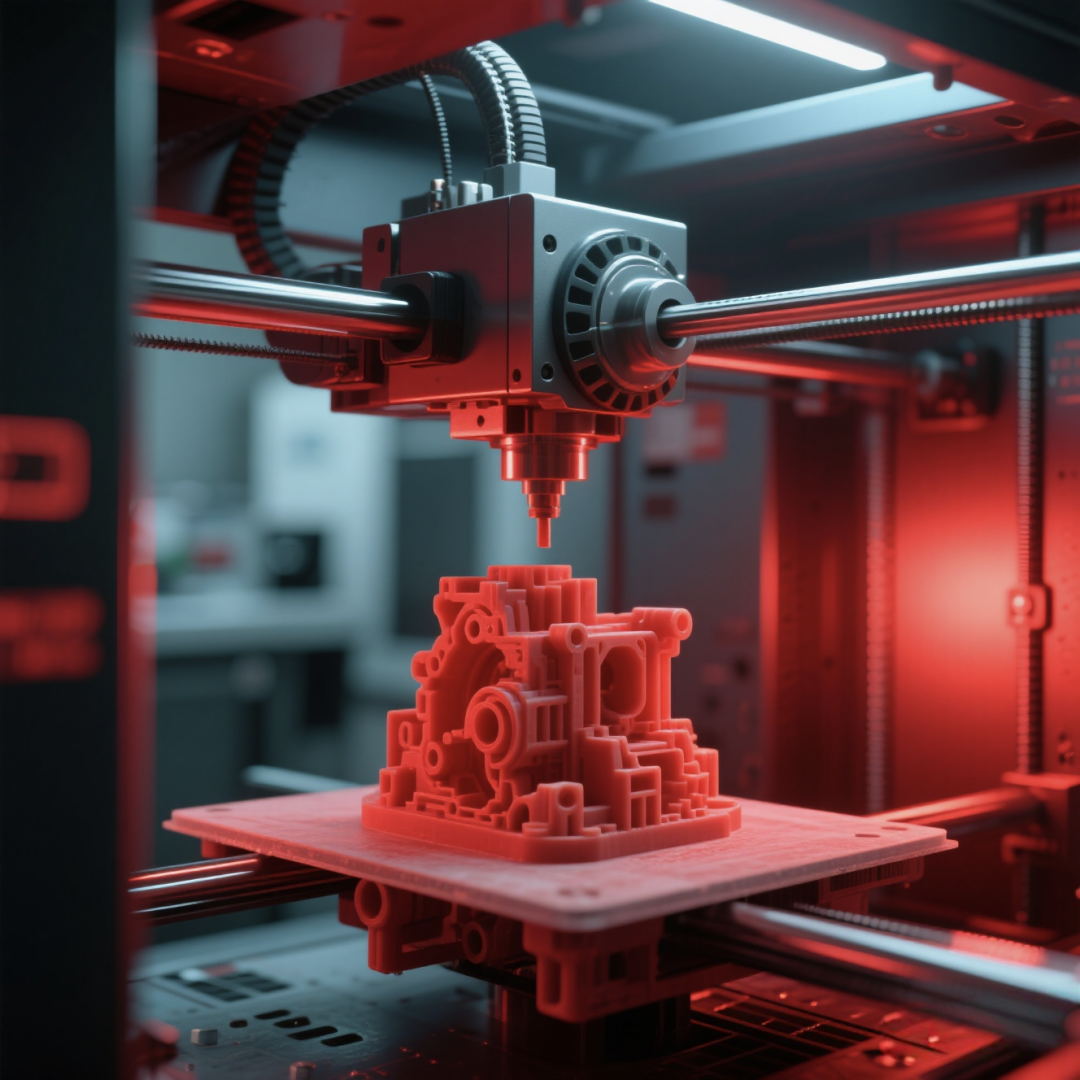

Ushering in a New Era of Precision Manufacturing

In today's era of rapid technological development, 3D printing technology has gradually penetrated into various fields and become an important part of modern manufacturing. Among numerous 3D printing materials, red wax, with its unique performance advantages, is gradually emerging, bringing us an unprecedented manufacturing experience.

Red Wax Precision Printing Technology

Red wax 3D printing technology has many significant advantages. It boasts extremely high precision, achieving ±0.05mm or even higher accuracy, with a tolerance as low as 0.5 per thousand. It can perfectly replicate complex textures, fine lines, and subtle curved surfaces, meeting various precise size requirements, which makes it excel in fields with strict precision demands. Meanwhile, the printed models have a smooth and delicate surface with a full texture, and the 纹路 are negligible, making subsequent processes such as polishing, buffing, and painting easier, thus greatly saving post-processing time. Additionally, red wax materials have certain hardness and strength; although they are relatively brittle overall with insufficient toughness, they can meet the basic needs of most models in terms of display, assembly testing, and other aspects.

Red Wax in Multiple Fields

New Potential of Red Wax

Although red wax 3D printing has achieved remarkable results so far, with the continuous progress of science and technology, its development potential remains huge. In the future, the printing speed is expected to be significantly improved, thereby increasing production efficiency and meeting more large-scale production needs. In terms of materials, researchers are also exploring to further optimize the performance of red wax, enhance its toughness, reduce its sensitivity to the environment, and expand its application scenarios. It can be predicted that in the near future, red wax 3D printing technology will play a key role in more fields, bringing more surprises and changes to our lives.