Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

Innovative integration of precision manufacturing

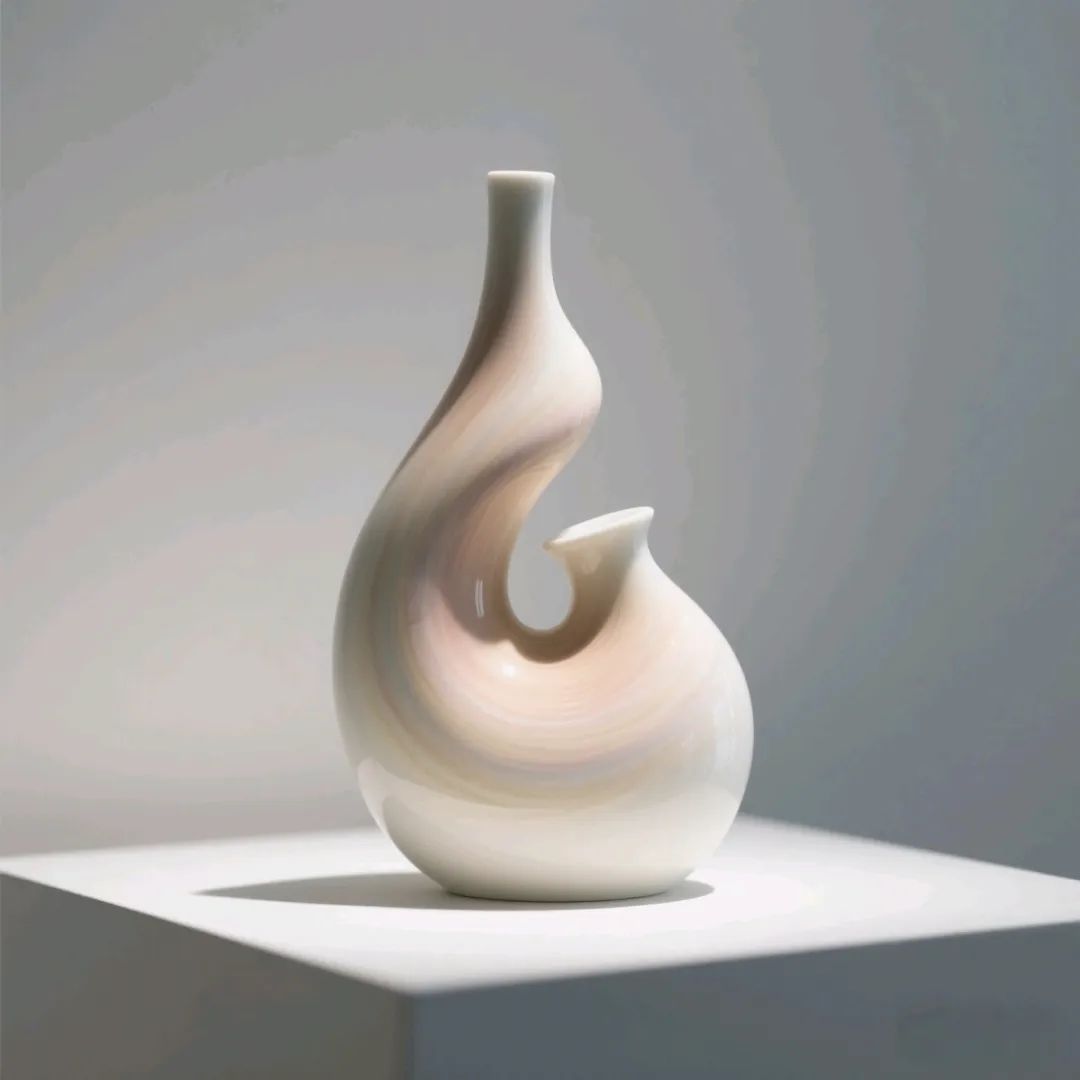

In modern manufacturing, ceramics, with their excellent physical and chemical properties, have become a key choice for high-end manufacturing. CNC (computer numerical control) machining technology offers a revolutionary solution for the precision molding of ceramics. The combination of these two technologies not only breaks through the bottlenecks of traditional ceramic processing but also drives precision manufacturing towards higher precision and more complex structures.

Ceramic CNC adapter

The compatibility of ceramic material properties with CNC machining is fundamental to their coordinated development. Ceramics offer significant advantages such as high strength, hardness, high temperature resistance, and corrosion resistance, but they are also brittle and difficult to process. Traditional machining methods struggle to meet the precision requirements of ceramic parts. However, CNC machining, which uses computer programs to control tool movement, can achieve micron-level machining accuracy, making it a perfect match for the machining needs of ceramic materials. Whether it's structural ceramics like alumina and zirconia, or engineering ceramics like silicon nitride and silicon carbide, CNC machining can achieve precise shaping of complex shapes by optimizing tool paths and cutting parameters.

Precision machining core

Key machining technologies and process optimization are core aspects of ceramic CNC machining. Because ceramics have a hardness exceeding HRC50, ordinary metalworking tools are inadequate, requiring the use of diamond or cubic boron nitride cutting tools. During machining, layered cutting and low feed rates are required to reduce material stress and prevent brittle fracture and scrap from the ceramic. Furthermore, the design of the cooling system is crucial. High-pressure cooling oil not only reduces cutting temperatures but also promptly removes machining debris, preventing scratches on the machined surface. With the application of five-axis CNC technology, surface machining accuracy for ceramic parts has reached 0.001mm, meeting the stringent requirements of aerospace, precision instrumentation, and other fields.

Ceramic application prospects

The expanding application areas and technological development prospects demonstrate the immense value of ceramic CNC machining. In the electronics industry, CNC-machined ceramic substrates provide efficient heat dissipation solutions for 5G base stations. In the medical field, zirconia ceramic dentures, through CNC machining, achieve a perfect combination of customization and biocompatibility. In the new energy sector, ceramic seals, thanks to their precision CNC-machined sealing surfaces, ensure the stable operation of hydrogen fuel cells. In the future, with the deep integration of AI technology and CNC machining, adaptive machining systems will enable real-time optimization of ceramic machining parameters, further improving machining efficiency and product quality, and promoting the innovative application of ceramic materials in more high-end manufacturing fields.