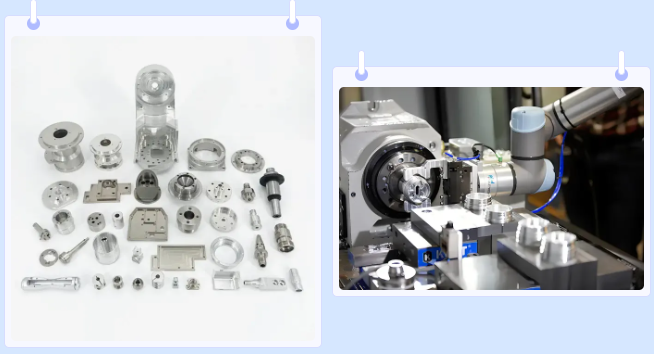

Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

The Wide-ranging Applications of Rapid Tooling in Daily Life

With the advantages of high efficiency, low cost and flexible customization, rapid tooling has been deeply integrated into the production of daily consumer goods, acting as an invisible driving force to improve the quality of life. In the home appliance sector, the R&D and mass production of most components—ranging from rice cooker inner pots and refrigerator drawer slides to the plastic casings of washing machine control panels—are inseparable from rapid tooling. During the new product R&D phase, rapid tooling enables sample production within days, facilitating quick verification of design feasibility and shortening the time-to-market cycle. For small-batch production, there is no need to invest in expensive traditional steel molds, which significantly reduces manufacturing costs and makes niche customized home appliances accessible to ordinary households. In addition, in the production of small commodities such as toys and stationery, rapid tooling can accurately adapt to complex shapes. Whether it is the detailed textures of cartoon dolls or the special-shaped structures of multi-functional stationery, it can achieve high-efficiency molding to meet the diverse needs of consumers.

In the automotive application scenarios, the application of rapid tooling covers interior trim, exterior trim and component matching, providing support for upgrading the driving experience. Interior parts such as dashboard decorative components, door armrests and air conditioning outlet grilles often realize personalized customization and rapid iteration through rapid tooling, adapting to the design styles of different vehicle models. Targeting the niche demands of the automotive modification market, rapid tooling can quickly respond to the production of customized accessories, such as personalized wheel hub covers and interior ambient light brackets, allowing car owners to easily build their exclusive vehicles. Meanwhile, in the automotive maintenance field, scarce components of some discontinued vehicle models can be reproduced via rapid tooling, which solves the problem of hard-to-find parts, extends the service life of vehicles, reduces maintenance costs and brings convenience to car owners.

In the fields of medical health and daily care

In the fields of medical health and daily care, the precision and efficiency of rapid tooling provide a guarantee for product safety and popularization. Household medical devices such as blood glucose meter casings, blood pressure monitor cuff connectors and nebulizer accessories need to meet strict dimensional accuracy and hygiene standards. Rapid tooling can accurately control production details while achieving small-batch and multi-specification production to adapt to different household scenarios. In daily care products, rapid tooling technology enables rapid response to market trends and timely launch of new products, such as molding molds for contact lens cases, beauty tool casings and disposable care products. In addition, rehabilitation aids such as crutch handles and wheelchair accessories can be customized via rapid tooling to fit the physical needs of different users, improving usage comfort, making personalized rehabilitation aids more accessible and adding convenience and warmth to life.