Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

With the further development of various forming technologies, the accuracy of parts is also constantly improving. Rapid mold manufacturing, as a type of tool that does not require any specialized auxiliary fixtures, can quickly transform CAD 3D models into 3D solid models, and is therefore favored by an increasing number of user groups.

How can rapid tooling be made to further reduce costs and increase efficiency in the manufacturing process?

In the traditional plastic tooling unchanged for hundreds of years in the process of molding methods, in recent years, the new process and new materials of rapid tooling in Industrial Man combined with the rapid prototyping method of metal 3D printing have made a new breakthrough in the mold manufacturing industry, and metal 3D printing technology has replaced the traditional CNC processing molding method of rapid mold. Gradually also obtained more and more customers and enterprise applications,the rapid tooling is widely praised.

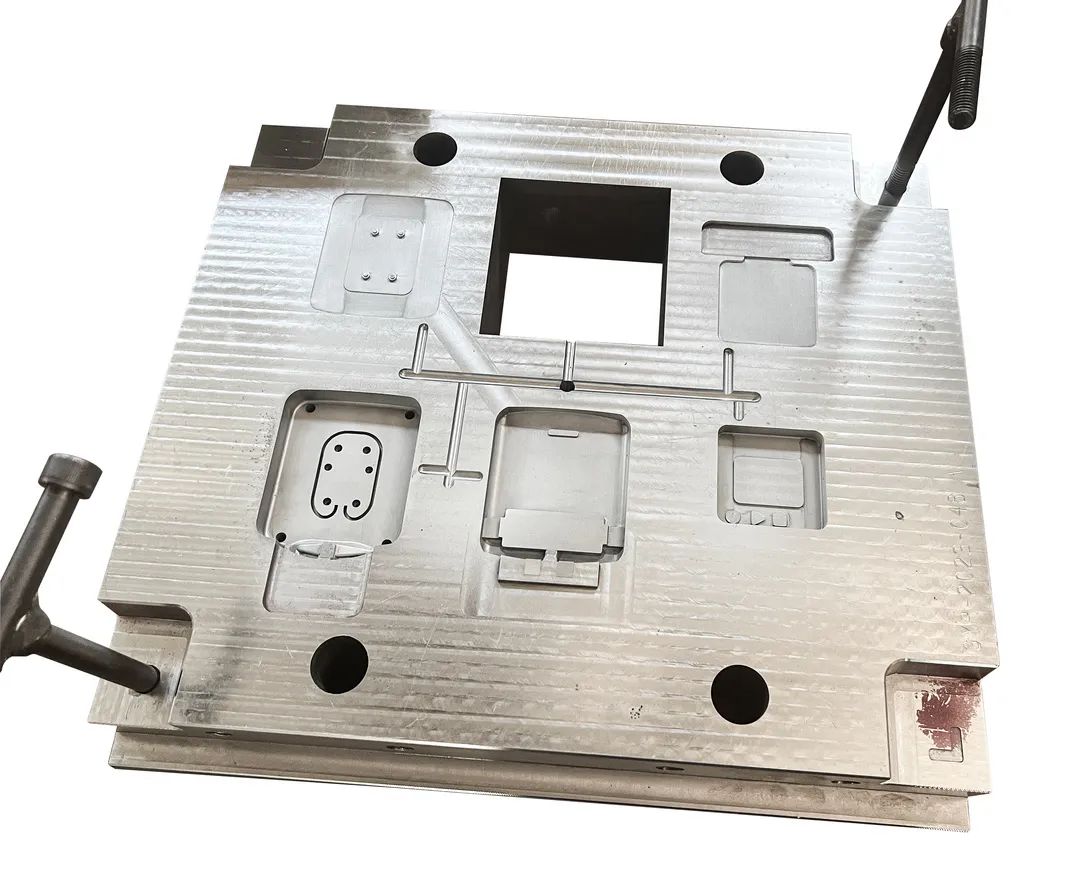

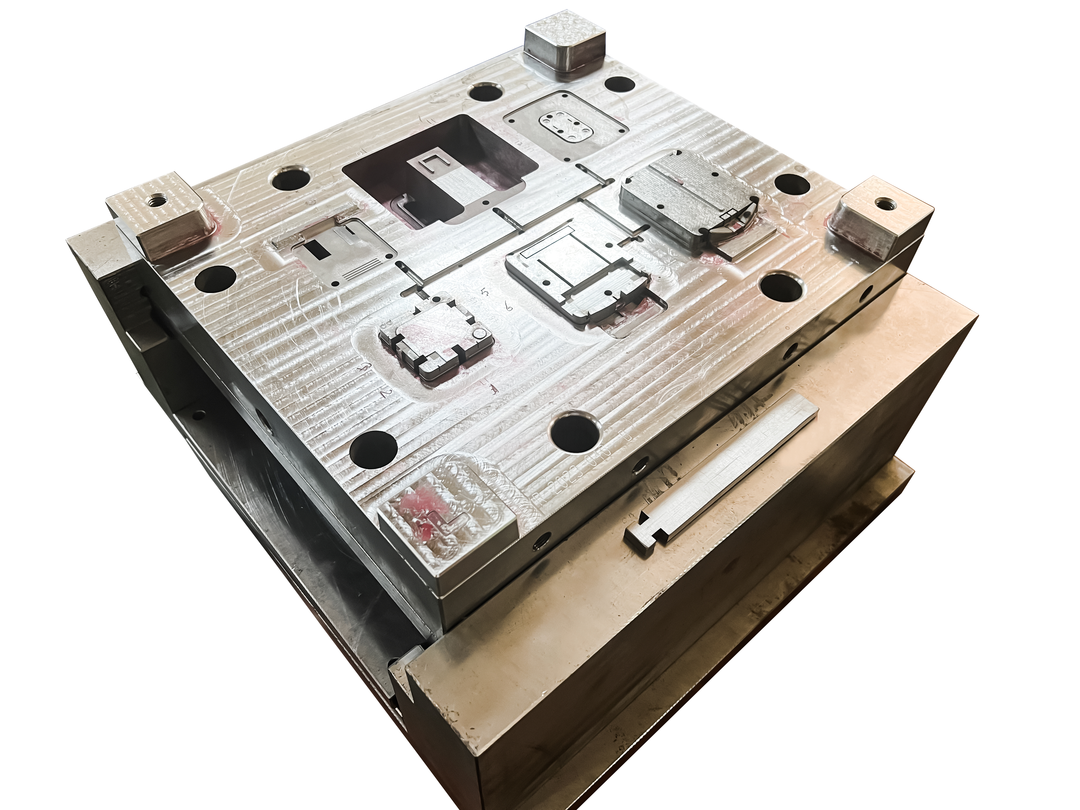

Traditional rapid tooling forming

The traditional rapid tooling using conventional die carrier, ejector pin, ejector plate and other multi-layer stacked assembly of the main body, mold structure using the traditional mold design, order material, CNC processing, wire EDM, gun drilling processing, EDM processing, grinding processing, a series of old-fashioned processing technology to complete a set of rapid tooling processing and forming methods. This manufacturing time is relatively long, many times it is difficult to meet the customer's needs on time.

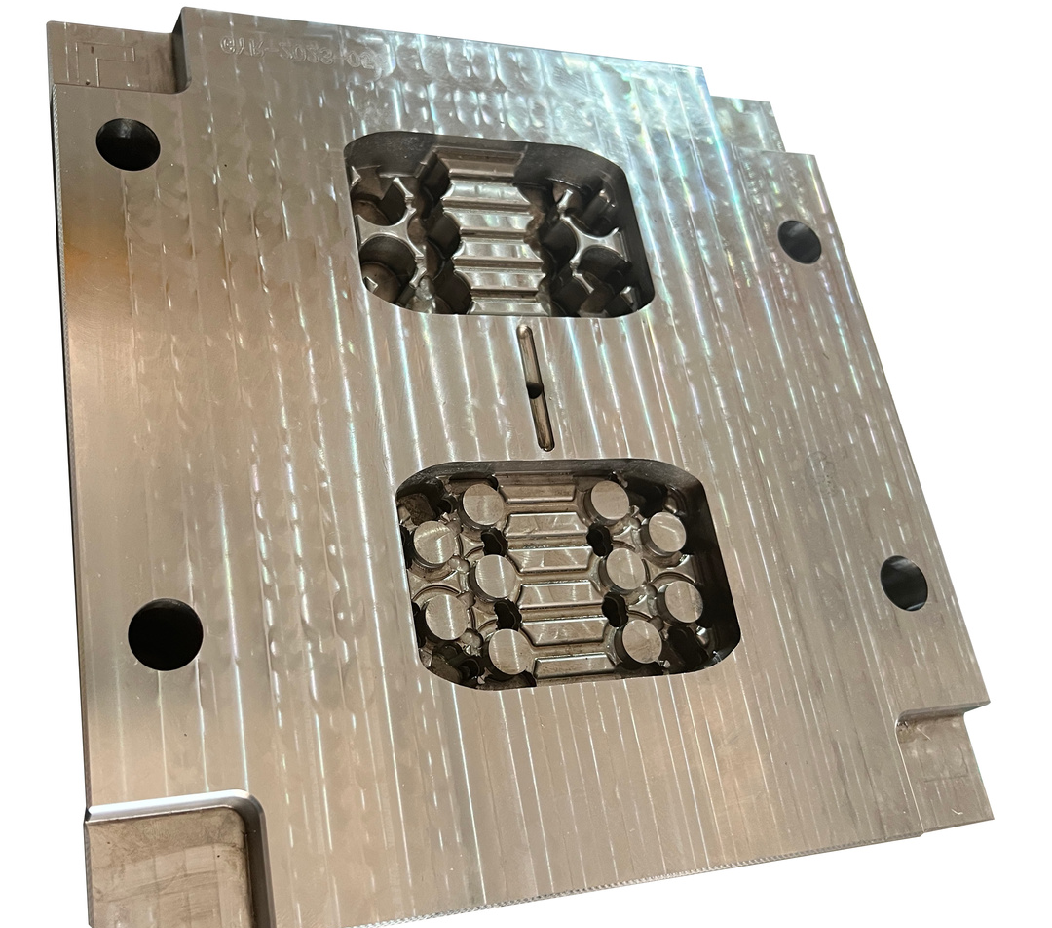

3D Printing mold manufacturing

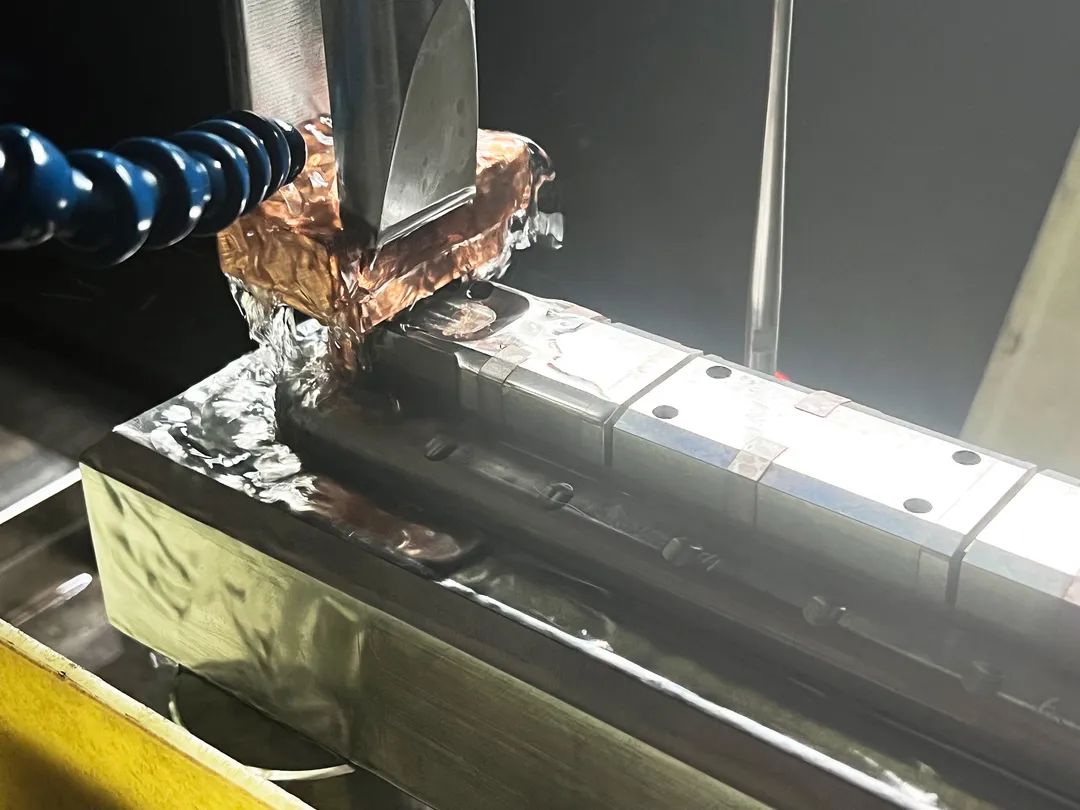

The new material combined with metal 3D printing technology can shorten the production period by 50% in the rapid tooling manufacturing process, and the production period can be accelerated at the same time, the manufacturing cost can be reduced. 3D printing mold, it is mainly fast in the printing equipment, this mold printing is a dual-laser, high temperature Stereo lithography Appearance (SLA), applying the speed of light to molding. Compared with the traditional tooling machining molding method, the speed of 3D printing and CNC machining speed are basically not on the same order of magnitude, and the speed of 3D printing molds takes advantage.

Processing Advantages of 3D Printing

The advantages of 3D printing for rapid tooling are as follows: First, omit the traditional tooling gun drilling process; Second, omit the wire EDM process; Third, it can also save the most time-wasting EDM process.In the manufacturing process of traditional tooling. tooling professionals know that the EDM of the tooling structure is one of the most time-consuming production processes. Since the Industrial Man with metal 3D printing process, the time and materials saved in the manufacturing process of rapid tooling can then open a set of duplicated rapid tooling.

Metal 3D printing tooling equipment 100 units

Industrial Man Product RP&M Co., Ltd. has 100 sets of metal printing tooling equipment, using advanced double laser, ultra-high temperature vibration speed of the forming technology. Focus on rapid tooling, test molds for small batch injection all kinds of plastic products, our rapid and simple tooling can be tested within 24 hours, and small batch injection products can be produced within 72 hours. Welcome customers who have demand for rapid tooling to pay attention to Industrial Man, so that you have unexpected harvest.

About Us

Industrial Man is a high-tech model design and manufacturing enterprise with product model design and manufacturing as its core, and providing comprehensive technical services as its business purpose. The main business includes: car styling, exhibition car production, car body stamping, sheet metal processing, rapid soft steel molds, hand samples, small batch production of aluminum alloy, small batch production of silicone resin molds, etc. If you are interested in our products and services or have any cooperation intentions, please feel free to contact us at any time. We look forward to working with you to create a better future together!