Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

What is the relationship between Rapid Tooling Manufacturing and Pinduoduo? In fact, they are not related to each other. However, if you use the Pinduoduo method to assemble and make rapid tooling or experimental mold, then the order price of mold manufacturing will be the same as that of Pinduoduo, and the manufacturing cost can be greatly reduced. Customers who place rapid tooling orders can also quickly get molds and required injection molding samples and products.

How to use Pinduoduo to process molds

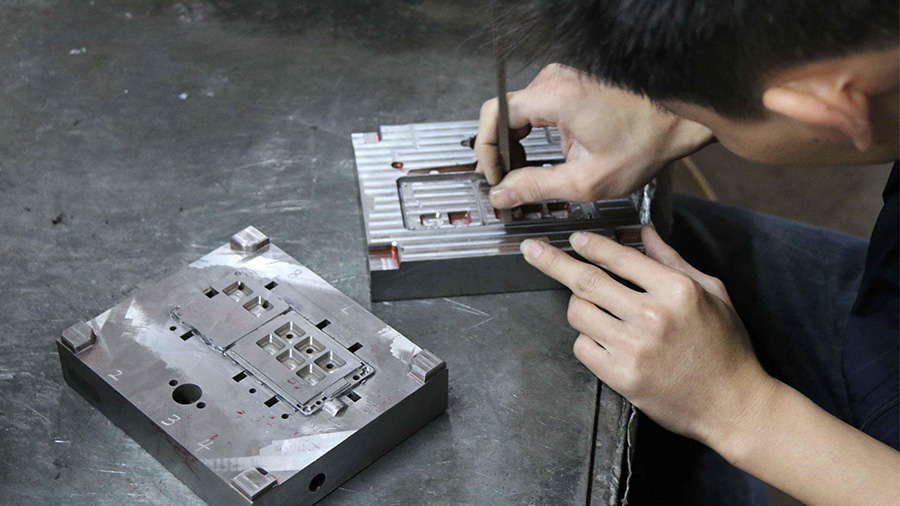

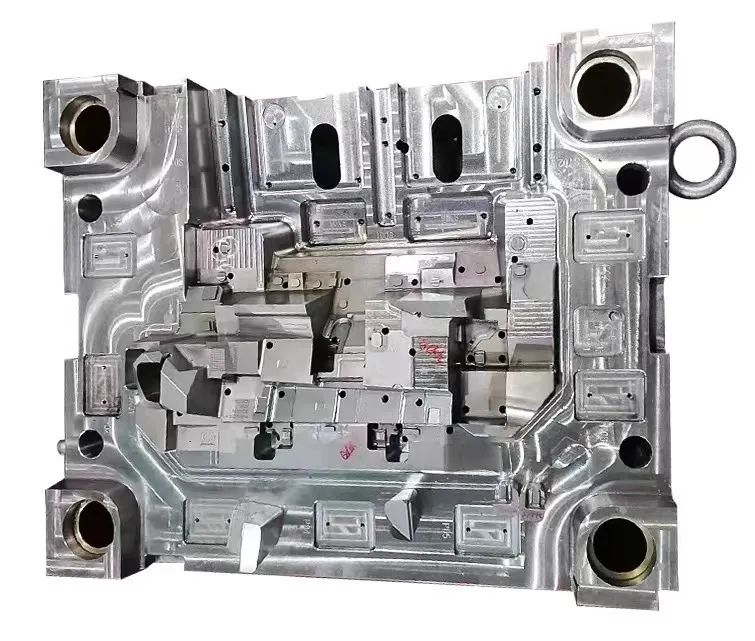

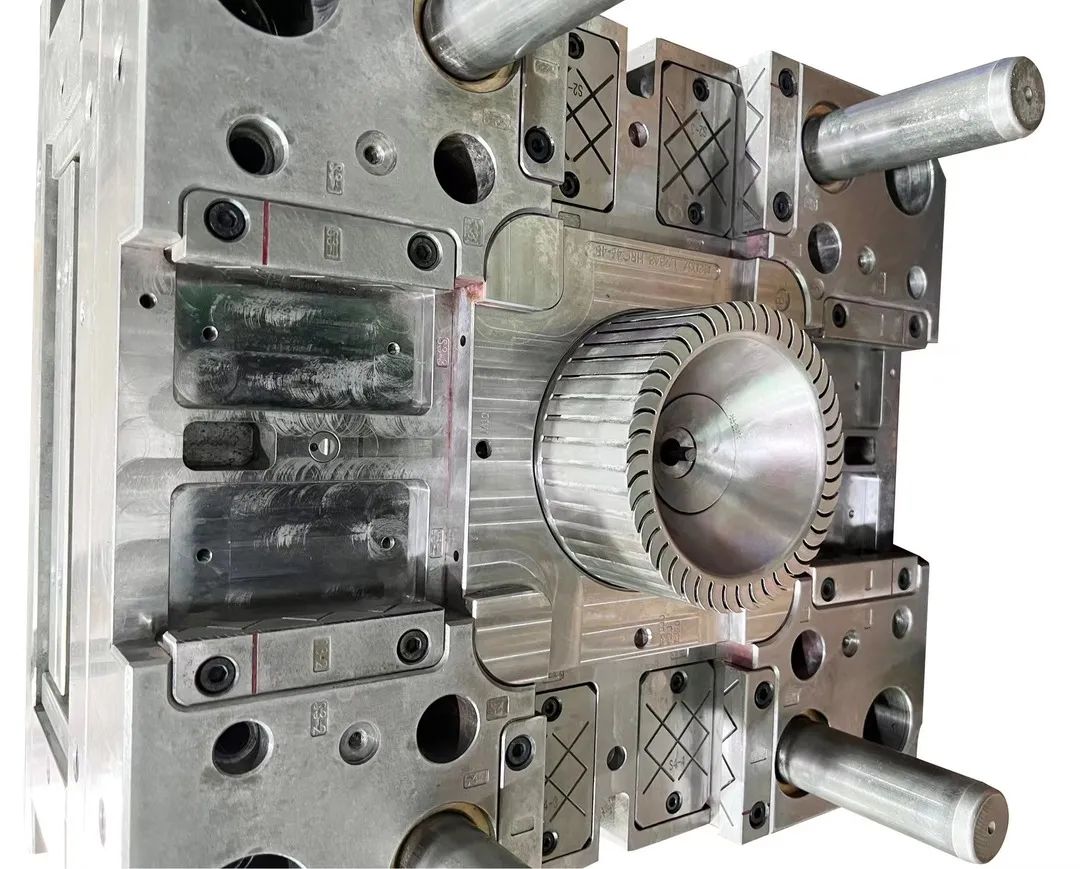

Industrial-Man manufacture rapid molds from the common mold base to reduce the cost of the mold, and from the rapid mold base to the common mold body. Just like consumer groups shopping on Pinduoduo, they can bargain by putting together the items they need to buy. Then when we are producing rapid molds, customers can also use joint mold processing to produce small batches of injection molding products. We combine two to three customers' products in a set of molds for processing and production. The biggest advantage of this production situation is that It can reduce the mold cost by 30% to 50%, and the cost of mold injection can also be reduced by about 20%.

In the period of market involution, the cost reduction of injection mold processing is the most important

Nowadays, in the period of involution in all walks of life, especially in the manufacturing industry, the involution is particularly serious. In order to develop better and get more orders from customers, we must consider the problem from the perspective of customers. Therefore, we are vigorously promoting the mold-clamping and mould-joining manufacturing method this year. With such a manufacturing method, the scattered customized products can be produced by the combination of industrial man's moulds, and the injection molding production process of rapid molds and rapid molds. At the same time, the production cost is reduced to about 50% by the use of combined mold manufacturing and mould-joining production, which also allows us to roll out a new direction of composite moulding.

Solutions for co-molding different products

Making different products with the same mold is like a mother giving birth to twins. Co-molding injection molding is aimed at the production of small products with individual parts, and the solution for small batch customization is particularly helpful. Such as doorbells, mobile phone brackets, smart controllers, pinhole cameras, lipsticks, lip balm boxes, and high-end packaging products. If you open a set of molds alone to make a small batch of about 1,000 sets of products, the cost is indeed high. In the industrial-Man company, when encountering rapid mold development for similar small products, we will communicate with customers in advance, and open different small products from multiple customers in a set of molds, and then carry out injection molding and production together.

Mold manufacturing also has a high degree of confidentiality

Some customers are worried about the low confidentiality in the processing of integrated molds. We avoid risks in this way. In the mold manufacturing process, the single-product mold core split method is used, and then the mold base combined type is used to integrate several different product molds into one for injection molding. This production method enables customers of any product to come to the factory to see the processing process of the rapid mold, and the mold core is taken out separately to show the customer the production progress and production quality, and there is no possibility of any leakage of molds and products. Industrial Man have a good reputation and have been in business for more than 20 years, and there has never been a leak.

Industrial man's advantage

Because of focus, so professional; because of professional, so more worthy of your trust. As a well-known enterprise centered on product model design and manufacturing, Industrial Man not only covers a wide range of business, but also has high-end technology and mature craftsmanship in CNC machining, sheet metal stamping, and rapid tooling. Moreover, we always take meeting customer needs and customized experience as the highest service tenet, and continuously improve service quality and manufacturing level. It is precisely because of these advantages that industrial Man have absolute confidence and strength to look forward to your choice!