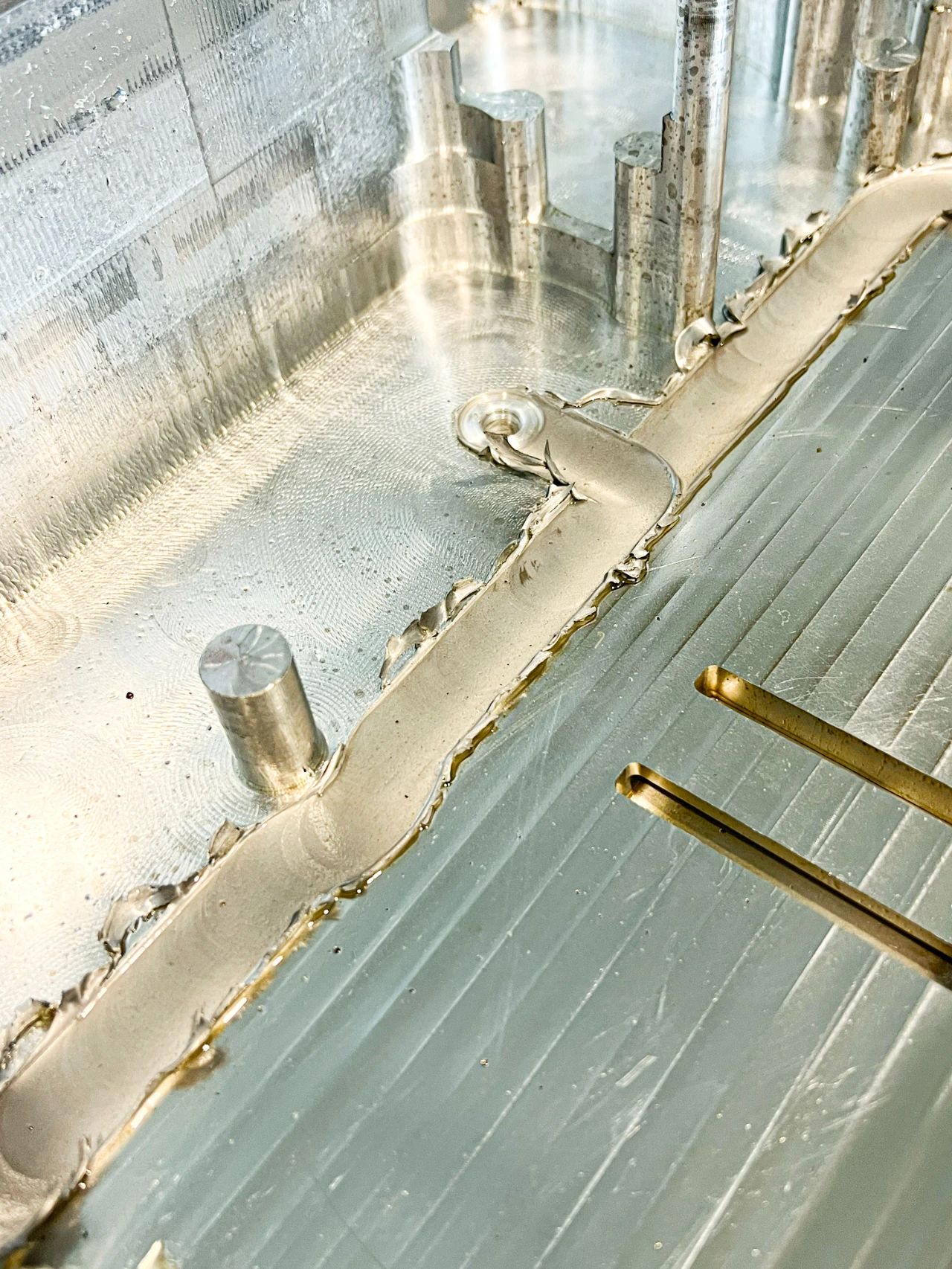

Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

3D printing can replace friction welding technology

3D printing can replace friction welding technology, which refers to the use of 3D printing technology (also known as additive manufacturing) to achieve the connection of metal components without the need for traditional friction welding processes. Traditional friction welding is a method of producing high temperatures by applying pressure and friction between the surfaces of two metal parts, causing the surface of the metal parts to melt and form a connection. Through 3D printing technology, metal materials can be directly stacked layer by layer to construct the required components, without the need for traditional welding or connection processes. This method can achieve a sturdy connection of metal components by melting and solidifying metal particles or wires between different layers.

The difference between 3D printing and friction welding technology:

3D printing technology and friction welding technology are two different manufacturing technologies, which differ in principle, application, and characteristics. Firstly, manufacturing principle: 3D printing technology constructs objects by stacking materials layer by layer, which is additive manufacturing. Friction welding technology generates heat on the metal surface by applying pressure and friction, causing the metal to melt and form a connection. Difference 2, Material Selection: 3D printing technology can use multiple materials, including plastics, metals, ceramics, etc. Friction welding technology is mainly applicable to the connection of metal materials, such as aluminum alloys, titanium alloys, etc. Difference three, manufacturing complexity: 3D printing technology can produce complex geometric shapes and internal structures, including cavity structures, curve shapes, etc. Friction welding technology is mainly used to connect metal materials, making it difficult to achieve complex geometric shapes.

Advantage comparison

Comparison of advantages between 3D printing and friction welding technology:

(1) Complex geometric shapes: 3D printing technology can achieve complex geometric shapes and internal structures, while friction welding is limited by material shape and process, and is suitable for parts with relatively simple structures. Through 3D printing technology, components with complex internal channels, thin-walled structures, or cavity structures can be directly manufactured to meet specific application requirements.

(2) Flexibility in material selection: 3D printing technology can use various metal materials, such as titanium alloy, stainless steel, aluminum alloy, etc. Greater flexibility in material selection to meet specific application requirements.

(3) Lightweight design and optimized structure: Through 3D printing technology, lightweight design can be achieved by creating cavity structures or optimizing structures inside components, reducing material usage, reducing weight, and improving performance.

(4) Manufacturing efficiency and fast iteration: Compared to traditional welding or connection methods, 3D printing technology can achieve rapid prototype manufacturing and extremely short production cycles, reducing manufacturing time and costs. This makes rapid iterative design and customized production possible.

Suitable manufacturing technologies need to be selected based on specific application needs and material characteristics. 3D printing technology is suitable for rapid prototyping and customized production, while friction welding technology is suitable for the connection and manufacturing of metal components. The two technologies have their own advantages in different fields and applications, and suitable manufacturing methods can be selected based on specific situations.

Industrial 3D printing strength

Shenzhen Industrial Rapid Prototyping Technology Co., Ltd. currently has 50 single head and double head metal printing equipment, as well as 25 plastic printing equipment, with a maximum printing part size exceeding one meter. Currently, our company can print metal materials such as aluminum alloy, stainless steel, titanium alloy, high-temperature alloy, copper alloy, mold steel, etc., plastic printing materials such as PA12, PA11, PA6.TPU, PP, PPS, and photosensitive resin, We now undertake various parts printing businesses worldwide. We will provide you with efficient customized processing services, and industrial people look forward to working with you!

Contact number: 13602550056(余先生)

Service hotline: 0755-81734556

Email hosting service: gyr@vip.163.com

Hubei factory address: No. 2, GUANGZHOU Avenue, TIEHSAN District, HUANGSHI City, Hubei Province

Address of HUMEN Factory: BUILDING 6, NO. 9 PUJIANG ROAD, DANING, HUMEN TOWN, DONGGUAN CITY

Company Address:D, E, F, G, 19th Floor,RUIJUN Building, No. 108 SAHNGXING Community Central Road, XINQIAO Street, BAO'AN District, SHENZHEN