Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

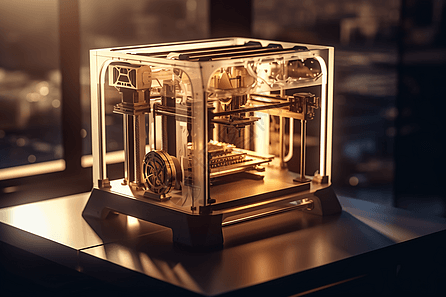

01 High-end customized titanium alloy 3D printing service

High-end customized titanium alloy 3D printing service is a kind of personalized, high-precision 3D printing service made of titanium alloy. It combines the advantages of 3D printing technology and titanium alloy materials to provide customers with customized parts, components or products.

02 The process of high-end customized titanium alloy 3D printing

1、 Requirements analysis and design:Analyze and discuss detailed requirements and design with customers to understand their product requirements, technical specifications and performance needs. It is that customer expectations and requirements are met during the printing process.

2、CAD Modeling and Optimization: Based on the client's needs, computer-aided design (CAD) software is used to create 3D models. At this stage, experts may optimize the model to ensure optimal structure and performance.

3、Material selection and parameter setting: Select a suitable titanium alloy material and set printing parameters, such as layer thickness, printing temperature, printing speed, etc. The selection of these parameters is critical to the quality and performance of the final product.

4、3D printing manufacturing: Using high-end 3D printing equipment, titanium alloy materials are stacked and melted layer by layer according to predetermined parameters to gradually build customized products. This process may take some time depending on the complexity and size of the product.

5. Post-processing and surface finishing : After completing 3D printing, perform post-processing steps such as removing support structures, cleaning and polishing the printed parts, and performing surface treatments such as spraying, anodizing or other coating techniques to improve the appearance of the product and performance.

6、Quality inspection and testing: Quality inspection and testing of customized titanium alloy products is performed to ensure that they meet design requirements and performance standards. This may involve visual inspection, dimensional measurements, material performance testing, etc.

7、Delivery and after-sales service:We deliver customized titanium alloy products to customers and provide necessary after-sales services, such as technical support and product warranty, etc.

03 Advantages of high-end customized titanium alloy 3D printing services

1. Design freedom: Titanium alloy 3D printing technology provides designers and engineers with greater design freedom. It can create very complex structures and shapes, including hollow structures, internal channels and optimized geometries. This enables innovative designs and optimizations that achieve more efficient and lightweight products.

2、Personalized customization: High-end customized titanium alloy 3D printing services can be personalized according to customer needs. Customers can customize the size, shape, function and appearance of the product according to their own requirements and preferences. This kind of customization can meet customers' needs for uniqueness and personalization and provide customized solutions.

3、Lightweight design: Titanium alloy is a high-strength, lightweight material that is an ideal for lightweight design. Through high-end customized titanium alloy 3D printing services, lightweight product manufacturing of complex shapes can be achieved, reducing the weight of parts and improving the fuel efficiency and performance of products.

4、Reduce the number of parts and assembly processes: With titanium alloy 3D printing technology, product structure can be simplified by integrating multiple parts into a single component. This can reduce the number of parts and assembly processes,reduce production costs and maintenance costs, and improve product reliability and durability.

04 Industrial Man’s 3D printing strength

Shenzhen Industrial Man Co.,Ltd. is located in Shenzhen city, Guangdong province. As a professional 3D printing manufacturer and industrial brand enterprise, our company brings together many professional 3D printing designers to serve 3D printing modeling in various industries and supports a variety of materials, such as actinic resin. , nylon, metal, etc., we strive to provide customers with one-to-one, professional customized services. With more than 20 years of experience in the industry,we have been widely praised by consumer groups for the integrity concept of rapid mould release in 4 hours, efficient and accurate quotation, effective mass production level technology. As a result, our company's 3D printing strength has not only won a steady stream of customer orders, but also built an important bridge for our company to cooperate with customers.

Contact number: 13602550056

Service hotline: 0755-81734556

Email hosting service: gyr@vip.163.com

Hubei factory address: No. 2, GUANGZHOU Avenue, TIEHSAN District, HUANGSHI City, Hubei Province

Address of HUMEN Factory: BUILDING 6, NO. 9 PUJIANG ROAD, DANING, HUMEN TOWN, DONGGUAN CITY

Company Address: D, E, F, G, 19th Floor,RUIJUN Building, No. 108 SAHNGXING Community Central Road, XINQIAO Street, BAO'AN District, SHENZHEN