Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

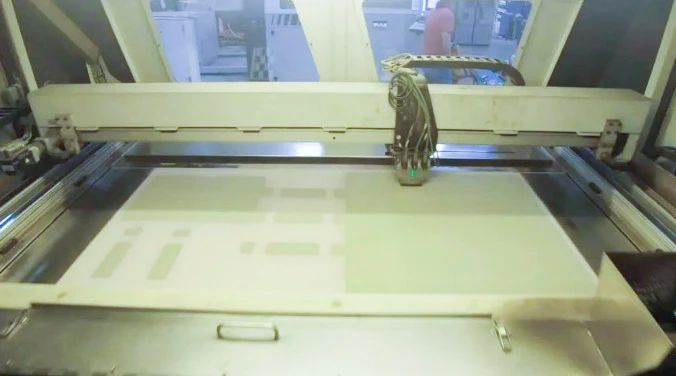

Sand mold printing technology

3D printing sand mold additive molding originated from the ancient sand mold casting molding technology. It was realized through scientific experiments with additive new materials and years of 3D printing. In recent years, for some small batch aluminum alloy prototype parts with complex structures, especially motors of new energy vehicles, extended range hybrid engine casings, etc., we have come to the following conclusions: In the early stage of proofing and small batch casings In the test, using sand mold printing and then performing the aluminum alloy casting process is the most time-saving and manufacturing cost-saving method.

Advantages of sand mold technology

In recent years, most factories have adopted 3D printed sand molds, which are completely printed molds. There is no longer a need to do what was done ten years ago: first make a prototype of the product and then surround it with sand. The passage of time has brought technological updates. What industrial people have introduced in the past two years is to directly use new materials and 3D printing technology. After printing the sand mold, it is directly cast into aluminum, eliminating the need for a prototype manufacturing process. This kind of The sand mold casting process is widely used in the development of extended-range new energy vehicles.

Sand mold has high strength

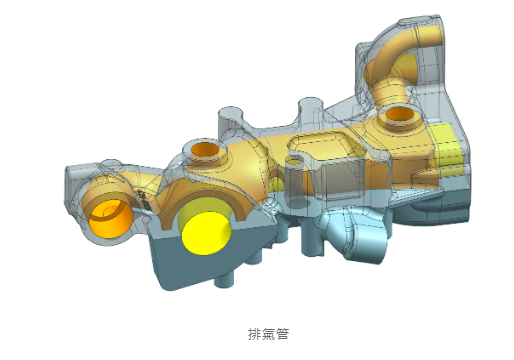

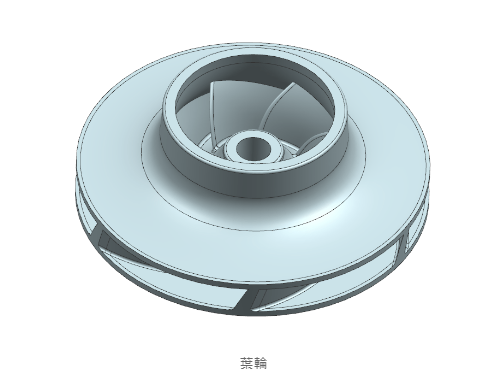

The mold life of sand mold casting in rapid prototyping prototypes reaches 200 times. The cast prototype prototypes are fully consistent with the physical properties of future products and can be used for performance verification in various automobiles. The prototype cycle is short and the cost is low. The mold cost of the aluminum casing of Cheng's engine can be controlled within 20,000 yuan. The aluminum shell is priced according to weight, and the casting cost will not exceed twice the material cost.

Sand mold recyclability

Sand mold raw materials, also known as additive new materials, are mainly composed of river sand or river sand, and a special curing agent is added. Through the light-curing molding method of 3D printing, the sand body is laminated to achieve a specific product appearance and structural shape, and a complete mold is made. After the casting is completed, the mold can be broken and reused, which can To reuse old materials, the material waste rate in the intermediate process does not exceed 5%. It is precisely because of this characteristic that it can indeed be regarded as a new and advantageous new material in the manufacturing industry.

About Shenzhen Industrial Man

Shenzhen Industrial Man Product RP&M Co.,Ltd is an enterprise specializing in CNC and stamping machining, new auto parts research and development, 3D printing development and services. It has now become the first rapid prototyping enterprise in Guangdong Province to introduce 3DP sand printing equipment. Through the intelligent transformation of 3D printing, Established green, flexible, high-end rapid sand mold casting capabilities.