Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

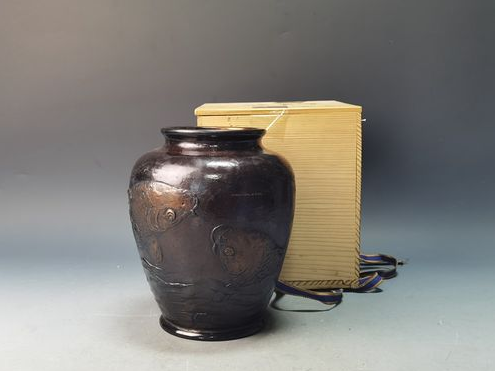

01、Wax Casting

Wax mold casting is a precision, small-batch metal parts manufacturing process that is commonly used in automotive engines, range-extended engines and new energy electric vehicle drive motor components. In terms of performance, this process is more suitable for use in early product prototyping, as well as in the trial and testing stages of small batch trial production projects.

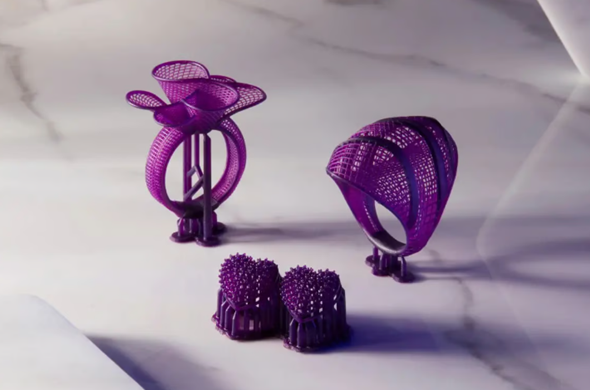

02、Wax molding - 3D printing

Wax molds are basically formed using 3D printing technology. After the wax mold is formed, workers need to inject the liquid that the required metal material melts at high temperature into the mold through pouring, so that the product can be quickly formed in the mold. Compared with other manufacturing processes, the advantage of wax molds is that they can produce one product from one mold and multiple products from one mold. At the same time, different metal materials can be selected for casting molding, which can achieve high-efficiency production while saving materials.

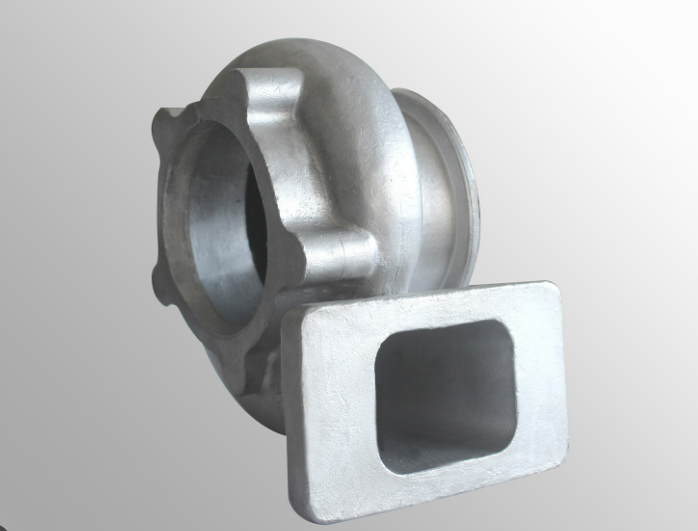

03、CNC Machining after wax casting

After the wax mold is cast, the prototype usually requires CNC precision machining. The advantages of wax molding are mainly for hollow body products. After pouring, a tooling fixture must be designed to transfer the metal parts cast from the wax mold to the CNC machine, and then perform secondary precision drilling and precision machining of the mounting position. Five-axis CNC machining machines are more commonly used. After a set of operation procedures, the precision of the final installation position can reach the H8 standard, and the precision tolerance can reach 0.001 mm.

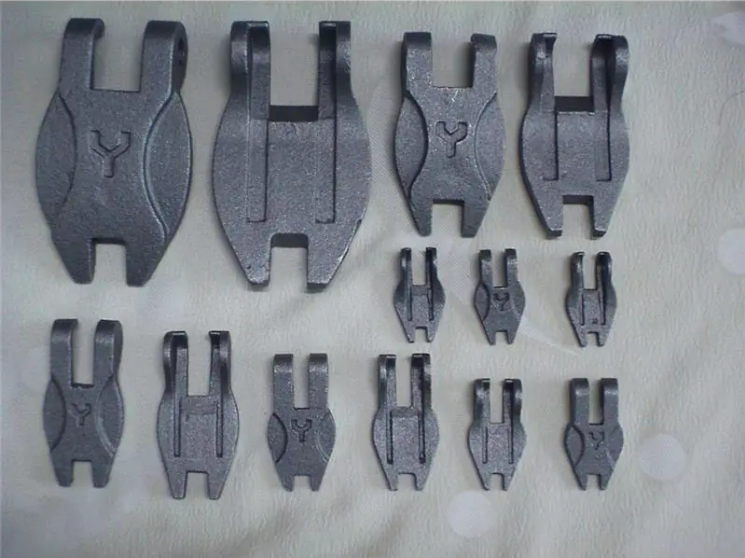

04、Small batch precision control of wax casting

Wax mold castings are generally made of stainless steel and aluminum alloy products. Especially for stainless steel parts, the proofing is more complicated, so the accuracy must be good, and the requirements for tooling and fixtures are relatively high. The CNC used requires five-axis linkage, and the tools and tool holders need to be equipped with high standards. The processing of this kind of parts is all on-machine inspection, and the equipment cannot be used to inspect it separately after processing. Just like many high-precision parts, they are more on-machine testing, so as to ensure the production of high-quality prototype parts.

Sheznzhen Industrial Man

In addition to the above characteristics, wax casting has many advantages: it can produce castings with complex shapes, it can produce thin-walled parts with small holes, it can use various metals and alloys, and it has high precision. For wax casting, Industrial Man have nearly two decades of processing capabilities. Our wax castings ship quickly and can be customized on demand. Our products are not limited to valve blanks, hardware parts, stainless steel, carbon steel, etc. We have an annual production capacity of 100 tons of precision castings, and our products are sold all over the world.