Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

Introduction: Precision Equals Productivity

In the micro-scale realm of industry, precision is the lifeline: A deviation exceeding 5μm (one-tenth the width of a human hair) in an aircraft engine blade can trigger systemic vibration failures, while a surface roughness surpassing Ra0.2μm in orthopedic screws may provoke biological rejection. This harsh reality, where millimeter-scale errors translate into billion-dollar losses, has elevated precision machining to the status of core competitive advantage in high-end manufacturing.

Precision Machining: The Accuracy Pyramid of Manufacturing

Precision Grade | Tolerance Range | Typical Applications | Core Equipment |

General Precision | 10-100μm | Automotive gears, Phone frames | 3-Axis CNC Machines |

Ultra-Precision | 1-10μm | Aircraft blades, Surgical tools | five-Axis CNC + Laser Systems |

Nano-Level Precision | <1μm | Lithography lenses, MEMS sensors | Magnetorheological Polishing + E-Beam Systems |

Case Studies:

• The Airbus A350's blade machining precision achieves ±3μm tolerance, resulting in a 40% increase in engine service life.

• The iPhone 16's chassis features an Ra 0.4μm surface finish, achieving a premium ceramic-grade tactile experience.

CNC Machine Tools and Five-Axis Technology: The Core Engine of Precision Machining

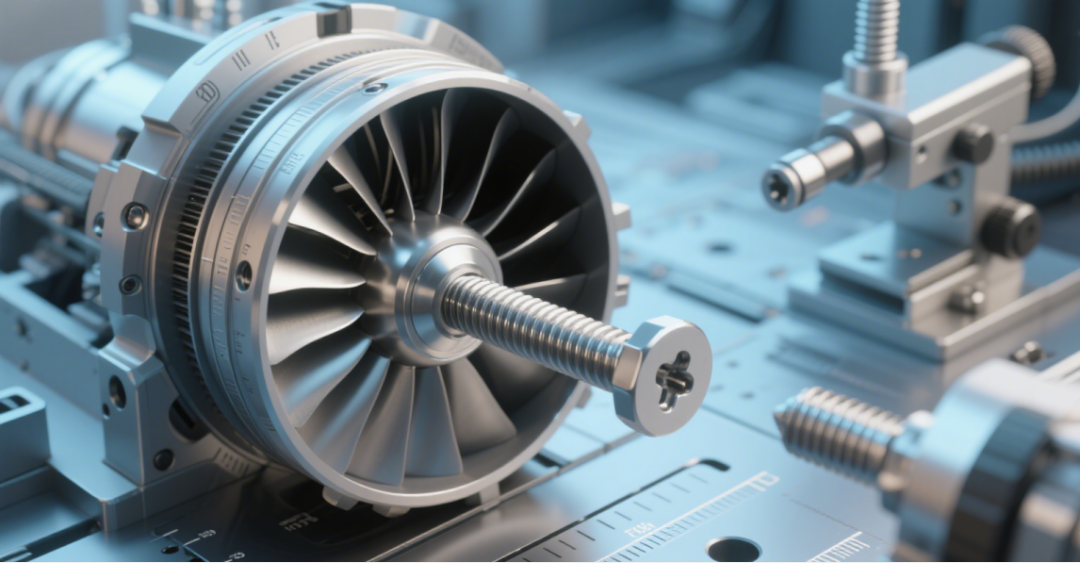

Five-Axis Simultaneous CNC: The Ultimate Solution for Complex Surface Machining

Technical Breakthrough:Simultaneously control the X/Y/Z three-axis translation and A/C axis rotation, eliminate the machining dead corners of traditional three-axis machines, and be competent for machining complex curved surfaces such as impellers and molds.

Precision Benchmark:DMG MORI five-axis machines achieve ±0.005mm repeatability (1/10 human hair width), aerospace impeller machining tolerance ≤±3μm meeting aviation-grade standards.

Efficiency Revolution:Automotive die manufacturer cuts processes from 12 to 4 with five-axis CNC, reducing cycle time by 60% and tool wear by 50%.

Smart CNC: From Mechanical Execution to Autonomous Decision-Making

AI-Powered Dynamic Compensation:The Mazak Integrex i-400 AM uses more than 200 sensors to correct thermal deformation in real time, with a compensation accuracy of ±0.01mm (the deviation within 1 meter is less than the thickness of an A4 paper).

Mazak Integrex i-400 AM utilizes 200+ real-time sensors for thermal drift correction,maintains ±0.01mm compensation accuracy (1m length deviation < A4 paper thickness)

Digital Twin Programming:The i5 system of Shenyang Machine Tool enables virtual simulation for pre - machining, which increases the programming efficiency of new operators by 80%. Meanwhile, the scrap rate in trial cutting is reduced from 5% to below 0.5%.

5G Remote O&M:The five-axis unit of Dalian Machine Tool supports AR remote debugging, reducing equipment downtime by 75% and operation and maintenance costs by 40%.

Industrial Excellence: Where Every Micron Counts

Industrial Man has always taken rooting technology in industry and serving manufacturing with precision as its original aspiration. Whether you need tolerance control of ±0.01mm or efficient machining of complex surfaces, we can provide integrated solutions combining equipment + process + service.

Call 13602550056 now to get a dedicated precision machining solution, or make an appointment to visit the factory for a live demonstration of five-axis machining.