Part Machining / Mould

Part Machining / Mould Sheet Metal / Hand Plate

Customize&Volume Production

English

English

Part Machining / Mould

Part Machining / Mould  English

English

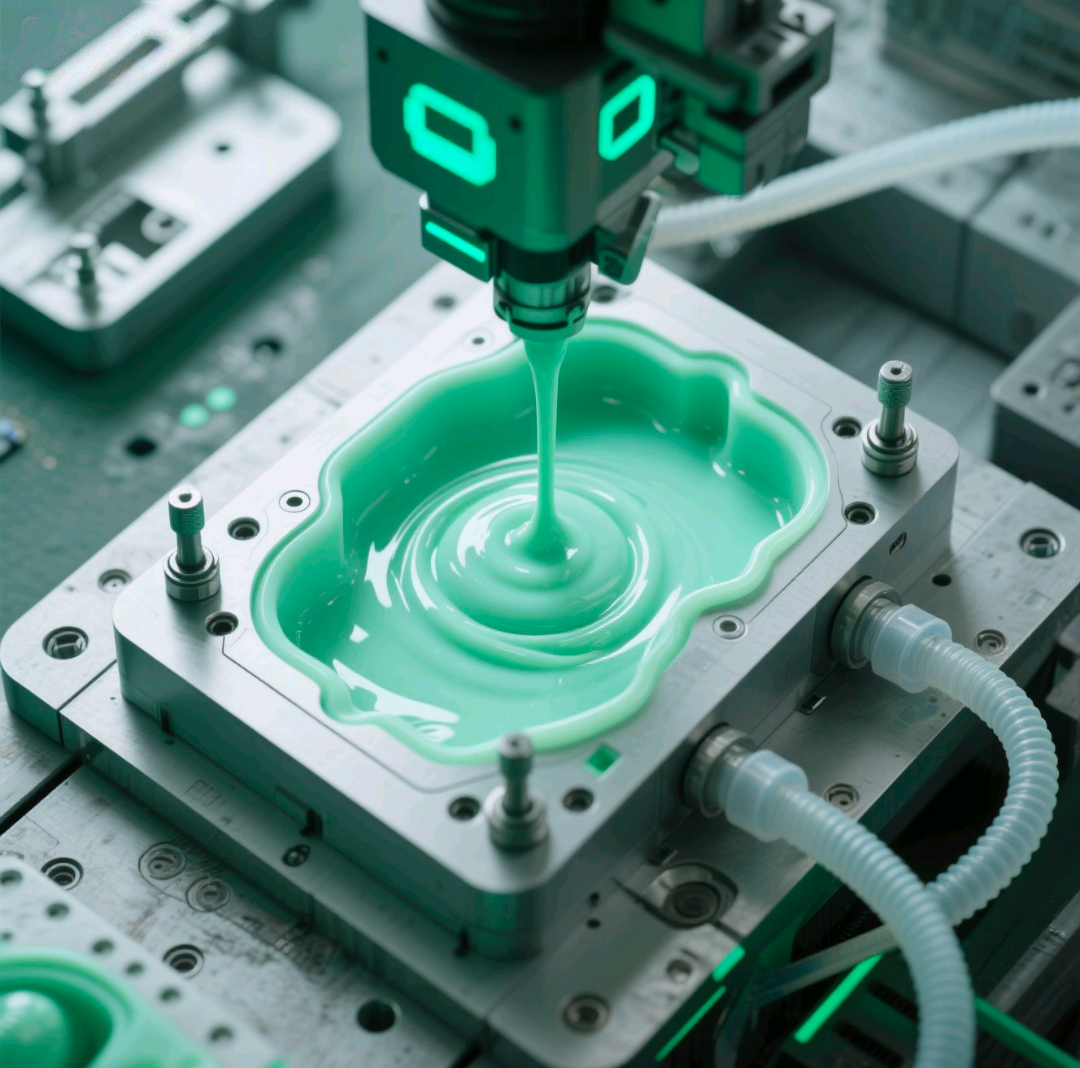

Silicone molding - the efficient code for industrial manufacturing

In the chain of industrial manufacturing, silicone Molding technology, with its unique advantages, has become a key link between prototype development and mass production. Especially in the small batch trial production scenario, this technology is being widely used with its efficient and flexible features. Below is a quick overview of this practical technology from three dimensions: process principle, core advantages, and application scenarios.

Process Principles

High-precision replication in three steps

The core logic of silicone Molding is to ‘use the prototype as a benchmark and use silicone moulds to reproduce it in bulk’, and the process can be divided into three key steps:

- Production of prototype parts: High-precision prototypes are produced through CNC machining, 3D printing (e.g. SLA), etc. The detailed accuracy of the prototype directly determines the quality of the replica mould;

- Making silicone moulds: After the prototype is fixed, liquid silicone is poured and vacuumed to remove the bubbles, and then cured to form a silicone mould that fits the prototype, the moulds can usually be reused 15-20 times;

- Vacuum injection: ABS, PC and other casting materials are injected into the silicone mould, which is cured and then demoulded to get the replica moulded parts consistent with the prototype, the whole process can be completed in a vacuum environment to reduce the air bubble defects.

typical application

Covering multi-industry R&D scenarios

Silicone replica moulds are used in a wide range of industrial application scenarios:

- Consumer electronics: rapid prototyping of mobile phone cases and smart wearables, testing feel and appearance;

- Medical Devices: Production of prototype medical device housings and accessories to assist with clinical validation and regulatory filings.

- Automotive industry: used for small-lot trial production of lamps and interior parts to verify the reasonableness of assembly;

For companies that require rapid iteration and small batch trial production, silicone Molding is the ideal choice for balancing efficiency and cost. Mastering this technology allows product development to be more competitive in the rhythm of ‘rapid trial and error, precise optimisation’.